Hydraulic Hole Punch Equipment

This 35-ton portable hydraulic punch press from Cleveland Steel Tool weighs just 31 pounds, is easy to use, and punches in seconds. The dual-action ssures easy linear operation. Unlike other similar tools, these punches will punch and strip inside a 90 degree arc movement of the lever. The upper rotary-style punch generates enough power to punch a 1/2 inch hole through 1/2 inch mild steel plate. The throat of the punch allows for punching…

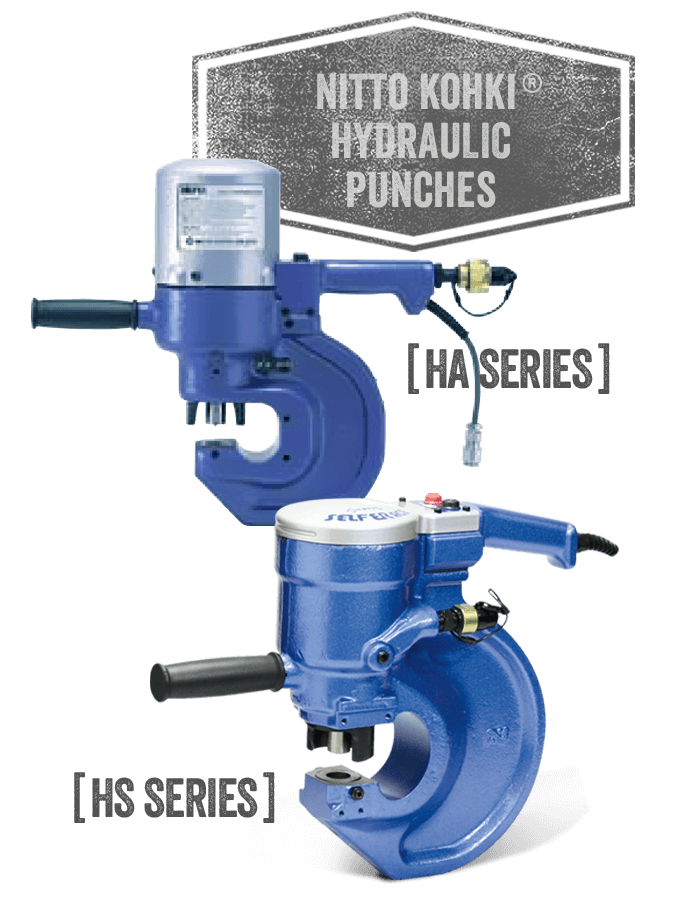

Gulf States Saw & Machine Co. is the ideal solution for hydraulic punching machines, suitable for a swift and precise punch of any specially-shaped holes like rectangular, square, H type e.t.c in various steels, brass, stainless steel, copper, aluminum, and many more. Our range of portable double-acting hydraulic punches is used in several industries for multiple operations.