What is universal ironworker

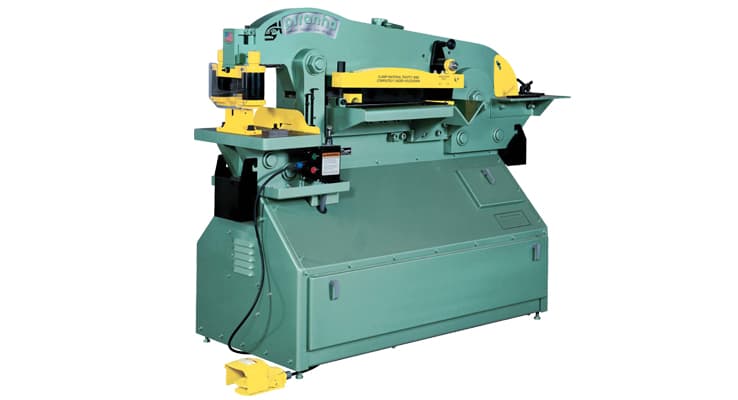

Dual Operator Piranha PII-88 permits simultaneous operation at both the punch station as well as shear/copper-notcher stations. This ironworker doubles your production with dual operation. It also includes advanced features such as the Automatic Urethane Keep Down on the Plate, Angle Shear and many other advanced features.

The Dual Operator Piranha PII 140 allows simultaneous operation at both the punch station as well as shear/copper notcher stations. This ironworker is the most powerful on the market and provides enough punching force to handle any application. It also has dual operators which makes it one of most productive.