Generators

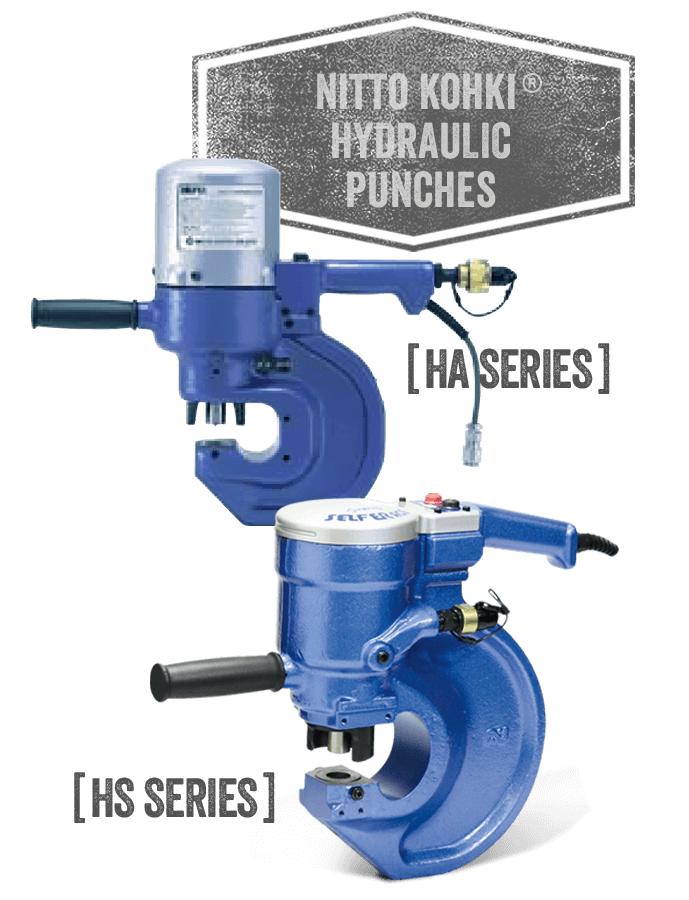

Well-designed puncher can punch holes precisely without shifting, thanks to its sturdy upper/lower molds. Perfect for L-shaped steels, channel steels, H shaped steels, and many other metal plates. It is widely used throughout the construction and electricity industries.

GSS Mchinery's line of portable hydraulic punches with double-acting hydraulic action is ideal for producing holes and slots quickly in various materials like beams, angle channels, plates, bar stock, and channel.