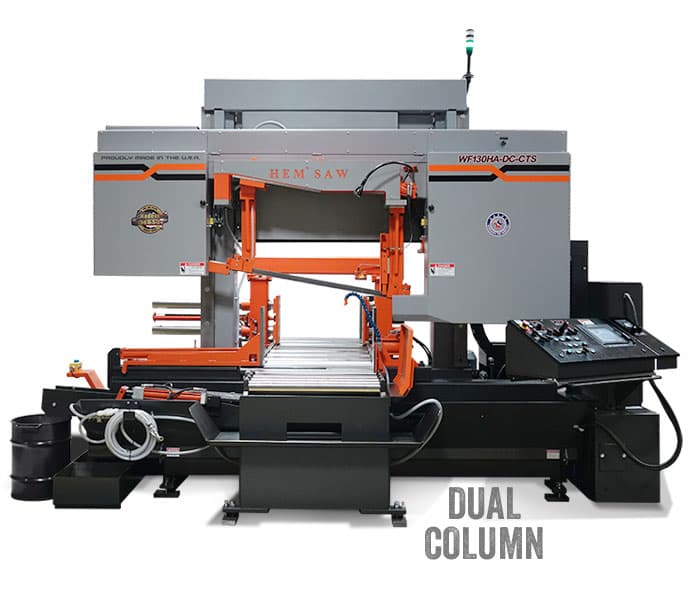

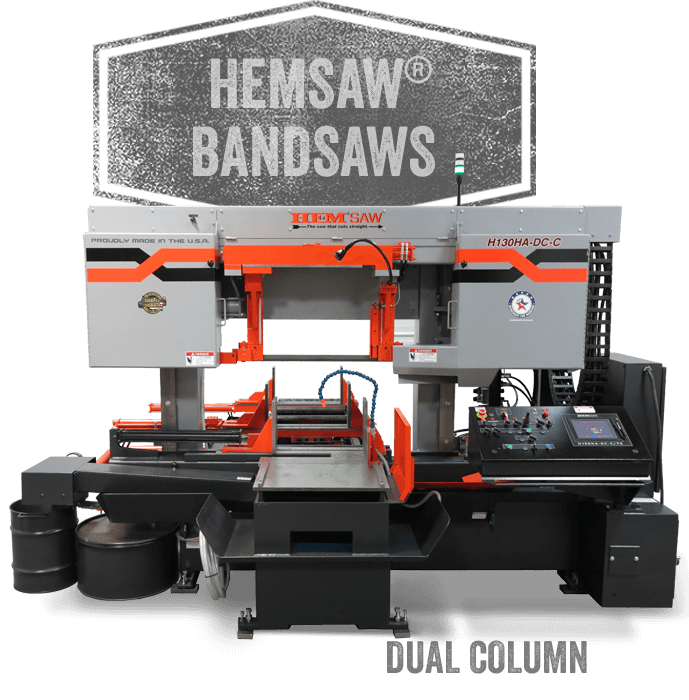

Cnc Band Saws

Tools

You can purchase a more expensive saw. However, DIYers will find this to be all they need.

Vertical bandsaws are, as the name implies. They are vertical machines that can be driven by an electrical motor with belt transmission.