Intro to Hybrid Pipe as well as Tube Benders!

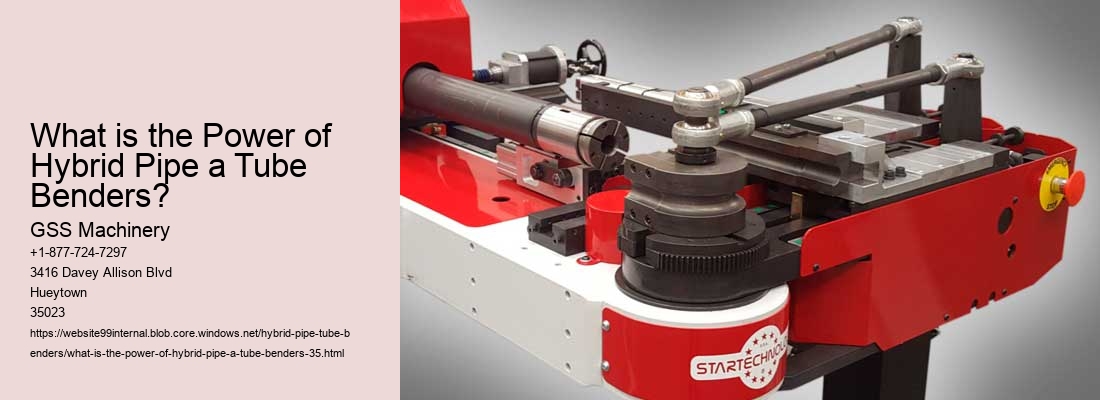

Pipe and tube benders are devices made use of in metalworking to develop a pipe or tube into a desired form. They come in 2 kinds: manual and hydraulic, and now there is an also far better choice on the marketplace - hybrid pipe and also tube benders! These revolutionary equipments integrate the very best of both globes, using superb accuracy with enhanced effectiveness.

Unlike hands-on models, hybrid benders are furnished with an electric motor that supplies more power than human strength can use. This implies that tighter curves can be accomplished with much less initiative from the operator. Additionally, these machines feature automated backgauging systems which assist make sure specific outcomes every single time. Yet what really establishes them apart is their ability to change in between different bending settings according to your demands - making them extremely versatile for any type of sort of project.

Moreover, hybrid benders are extremely easy to utilize thanks to their straightforward control panels. With plainly classified switches and also knobs, also newbie customers will certainly have no trouble navigating through the numerous setups. Additionally, they additionally include numerous safety and security attributes such as emergency situation stops and also safety shields that will certainly shield you from any kind of prospective accidents.

Altogether, hybrid pipe as well as tube benders supply irresistible performance at a budget friendly rate point - making them ideal for professionals trying to find a reliable device that won'' t spend a lot. Therefore, if you'' re in need of effective bending options without endangering on top quality, after that this may simply be the best device for you!

Finally, Hybrid Pipe & & Tube Benders offer terrific advantages when it concerns accuracy as well as comfort while being much more secure than standard techniques due to its integrated security attributes. This makes it an excellent selection for any individual seeking a trusted device at an accessible price point!

Hybrid pipe and also tube benders supply lots of advantages! They combine the very best functions of both hands-on and automated flexing devices, making them a functional device for any job. (Contractions: They'' re)From raised safety and security to enhanced accuracy, right here are several of the advantages of making use of these effective

machines. First, hybrid benders are much safer than traditional approaches. Manual bending can be hazardous because of the possibility for pinch points or various other risks associated with sharp bends. By comparison, a hybrid machine is created to prevent such threats while still creating limited curves without sacrificing accuracy. Plus, since they don'' t need manual work, it eliminates the requirement for employees to work in hazardous problems.

Moreover, hybrid benders can create intricate curves easily! The combination of automated and hands-on controls allows individuals to change bend angles swiftly and precisely; this enhances productivity dramatically contrasted to typical techniques. Furthermore, since they wear'' t require added tools or fixtures, there'' s no requirement for—extra configuration time-- just fill your product and start bending

! Additionally, hybrid pipe as well as tube benders use superb precision also! Unlike hands-on devices that depend on human sight alone to judge precision degrees, crossbreeds use sophisticated sensors that detect also little variances in a bend'' s angle or distance. This makes certain regular outcomes every time you use your maker—-- an essential feature when working with projects with specific specs!

Ultimately yet importantly (Interjection: Wow!), hybrids also save money in regards to maintenance expenses. Conventional models may need constant calibrations or adjustments that can lead to pricey repair services over time; nonetheless, hybrid makers are generally a lot more trusted as well as resilient than their counterparts—-- so you won'' t have to bother with spending extra cash money on upkeep!

Total (Transition expression), there are numerous benefits of using hybrid pipe as well as tube benders over conventional ones! From boosted security to enhanced precision as well as price financial savings in maintenance prices—-- these flexible tools supply a very useful resource for any project requiring accurate bends with marginal initiative entailed.

Hybrid pipe and tube benders are a kind of maker that permits individuals to bend pipelines as well as tubes easily. They are available in numerous sizes and shapes, making them suitable for different sorts of projects. With hybrid benders, you can develop curves, angles, circles as well as more with minimal initiative (and also even without the use of any special devices). You just require to feed the tube or pipe into the maker'' s flexing head and then permit the machine to do the rest!

There are numerous sorts of hybrid benders offered in the marketplace. The most usual type is an electric-hydraulic bender which utilizes hydraulic pressure to help flex steel sheets safely and also effectively. This type of bender additionally features a motorized source of power that assists speed up flexing process significantly. Another prominent alternative is a manual-hydraulic bender which needs manual procedure yet still produces impressive results. It has a hand wheel ran hydraulic pump that assists control the force applied on the material while it'' s being curved. (Both kinds need marginal set-up time.)

Additionally, there are some even more specific designs such as semi-automatic or programmable benders which permit users to preprogram details bends before launching the process. These equipments are great for bigger range production jobs as they provide repeatable precision every single time! In addition, there is an automatic rotating draw bender which benefits long straight bends. Last but not least, there is an induction home heating pipe bender which utilizes warmth created by electrical present instead of mechanical force to make tight bends in ferrous metals! Wow!

Overall, hybrid pipe & & tube benders use incredible comfort when it pertains to producing complicated shapes from metal materials swiftly and efficiently without compromising quality. Plus, their vast array of attributes makes them suitable for lots of types of projects, varying from little DIY jobs to big industrial applications!

Hybrid pipe and also tube benders are a wonderful brand-new device for all sorts of metalworking jobs! They offer a variety of features that make them the excellent selection for any kind of task. One significant benefit is their convenience; they can bend pipes and tubes of differing sizes, forms, and materials easily. They likewise come with both hand-operated and also electronic controls, so you can get the specific angle you need each time. Plus, these devices are incredibly long lasting as well as durable - they won'' t rust or rust in time!

Another fantastic attribute of hybrid pipe & & tube benders is their accuracy. With specific dimensions, you can be certain that each curve will end up specifically as you planned it to. You can likewise change the speed setups to get simply the right amount of force for each job. This makes them perfect for detailed bending tasks where accuracy is vital.

Lastly, these machines are unbelievably safe to make use of thanks to their safety functions such as protective shields and also guards. This minimizes the danger of injury while dealing with this machinery significantly! And also, lots of designs include an emergency shut-off button in case something goes wrong throughout operation.

On the whole, hybrid pipe & & tube benders have great deals of valuable attributes that make them crucial for any kind of metalworking project! From their flexibility to their safety attributes, these makers offer customers with every little thing they need to finish any task swiftly and also precisely (without sacrificing quality). So if you'' re searching for a trustworthy machine that carries out well whenever -after that look no further than hybrid pipe & & tube benders!

Applications of Hybrid Pipe and also Tube Benders are a vital aspect of producing procedures. They can be utilized in the manufacturing of vehicle, aerospace, industrial, clinical as well as lots of various other products. A hybrid bender (likewise called a mix bender) is an equipment device that integrates 2 benders into one unit for versatile flexing operations. It enables drivers to bend both round and square tubes with marginal arrangement time and no tool altering needed! The flexibility given by hybrid pipe benders makes them important in all sorts of industries.

As an example, in the vehicle market, they can be used to make exhaust systems or chassis parts. In the aerospace market, they are utilized extensively in the manufacture of aircraft wings or fuselages. Within commercial applications, they have ended up being essential for developing intricate shapes from tubing or pipes for numerous purposes such as hydraulic lines or cooling down systems. Even in medical applications, hybrid pipe benders play a vital role in producing tailored prosthetics or orthotics!

Moreover(,) hybrid pipe benders are likewise commonly embraced within artistic markets where their usage enables artisans to produce one-of-a-kind sculptures as well as ornamental pieces out of metal tubes or pipelines. With these functional machines at their disposal(,) musicians can style elaborate forms with precision as well as ease which would certainly otherwise be impossible using traditional techniques alone! Hybrid tube benders supply an unprecedented level of flexibility to understand craftsman enabling them to discover their imagination even additionally.

To conclude(,) it is clear that applications for Hybrid Pipe & & Tube Benders abound throughout many sectors because of their large range of performances! Their unique capability to integrate various flexing strategies makes them essential tools for creating cutting-edge solutions with maximum efficiency!

Hybrid Pipe & & Tube Benders are a wonderful device for dealing with steel pipes and also tubes. Nevertheless, they need proper upkeep to keep them running efficiently! Right here are some suggestions to aid you care for your bender:

First, constantly check the machine before use. Look for any signs of wear and tear or harm that might have happened in storage or transportation. You must also inspect all bolts to make certain they'' re limited and also secure.(This will certainly aid prevent crashes!)

Next, it'' s crucial to keep the location around your bender tidy as well as free from debris. This includes products like scrap steel, tools, and other components that can boost the threat of an accident or create damage to the machine itself. Additionally, make certain to oil the relocating components regularly according to supplier guidelines!

Ultimately, if something does fail with your bender, don'' t attempt to repair it yourself! Rather, call a qualified technician that is accredited in working with hybrid pipe & & tube benders. They'' ll be able to swiftly diagnose any type of concerns as well as supply you with suggestions on just how finest to continue.

In conclusion, by following these simple maintenance pointers for hybrid pipe & & tube benders you can make sure that your machinery stays risk-free as well as reliable for many years ahead! Keep in mind: great maintenance practices today can cause fewer issues in the future - so put on'' t skimp on it!

Safety And Security Procedures when Dealing With Hybrid Pipe as well as Tube Benders

Dealing with hybrid pipe and tube benders can be unsafe therefore it is very important to follow all safety and security procedures when using them. First of all, you should constantly use protective glasses, gloves, and also garments (specifically lengthy pants) to secure on your own from any type of flying stimulates or particles that might be produced. Second of all, never run a bender without the proper training or supervision from a skilled user. Third, make sure that there are no combustible products or liquids near the location of procedure as this could lead to severe injury. Fourthly, see to it that all electric cords remain in excellent problem and also away from any kind of water sources. Finally, never utilize a bender that is not in great working order as this can cause serious accidents!

In addition (shift phrase), prior to beginning work with a hybrid pipe and tube bender it is important to inspect the tools for any signs of damage or wear-and-tear. It'' s additionally necessary to look for loose fittings or broken parts which might cause a crash if made use of incorrectly. Furthermore, go through the maker’& rsquo; s guidelines thoroughly before usage; consisting of established details as well as safety and security standards. Additionally, constantly maintain your hands clear of moving steel items while operating the device; as these can promptly become very warm!

To conclude (shift phrase), by taking these precautionary actions when dealing with hybrid pipe and also tube benders you can considerably boost your safety while carrying out these tasks. Keep in mind: safety first!

Hybrid pipe and also tube benders are a terrific way to flex metal efficiently. They are effective devices, efficient in producing intricate shapes with accuracy. In conclusion, these machines are extremely effective and can help save money and time on projects that call for challenging bends! Not only do they have the ability to offer excellent contours immediately, but (they) additionally minimize labor prices by eliminating hands-on jobs. In addition, using hybrid benders gets rid of the threat of human mistake which can lead to expensive blunders! Therefore, it is simple to see why many people pick these makers for their bending demands. In conclusion, hybrid pipe & & tube benders use a reliable remedy for any type of metalworking job!

In addition, due to their convenience as well as comfort, hybrid benders are coming to be significantly prominent among enthusiasts too. With marginal initiative needed to operate them properly, any individual can end up being efficient at making use of one. In addition, when compared with various other types of flexing modern technology such as hydraulic or electrical designs, crossbreeds provide more affordability without giving up high quality or efficiency. Consequently(,) it'' s not a surprise that this type of equipment has come to be a go-to alternative for any person seeking trusted flexing results.

In short, there is no doubt that hybrid pipe & & tube benders offer remarkable benefits over traditional approaches of metalworking. From conserving both money and time to giving precision results with minimal initiative - they represent an excellent choice for nearly any type of application needing bends in steel tubing or pipes! Indeed, when you take into consideration all the advantages provided by hybrid benders - it'' s clear why they have actually ended up being so commonly utilized today!

Test tubes are available in several different materials: plastic, ceramic, metal, and glass. The most common materials are glass and plastic, while metal and ceramic is less common.

The benefits of tube bending are numerous, especially in terms cost-effectiveness, production efficiency and system performance. The cost of material, as well as the costs associated with storage, procurement and labour, can be reduced significantly by reducing expenses for additional fittings and connections.

Four elemental bending art is based on four classical elements: water, earth fire and air. Each element can be manipulated by certain martial arts styles that are reminiscent to the quality of the element.

Tubes can be used for medical devices, which require a precise outer diameter. It is important to know the outside diameter because it indicates how much can be held as a stabilizing factor. The capacity of pipes is important because they are used to transport liquids or gases.

The electron tube is also known as a vacuum tube. It consists of a glass or metal-ceramic enclosed device that controls the flow of electrons in electronic circuitry.