Sawing as well as cutting machines are (usually) made use of to cut, shape, or fabricate products into specific forms. They are crucial for numerous markets such as carpentry, metalworking, and also automotive repair work.

The procedure of using a saw or cutting maker starts with picking the proper sort of blade or tool. For instance, if you were aiming to cut through wood, it would be best to utilize a round saw blade as opposed to a jigsaw blade. The 2nd action is making certain the product is secured in position to make sure that it does stagnate while being serviced. Once these steps have actually been looked after, the operator can start the job available!

When running any kind of type of saw or cutting device it is very important to exercise caution and also adhere to all safety procedures including wearing protective gear like safety glasses as well as handwear covers. Additionally, drivers must maintain their hands away from the blades at all times—-- this consists of setting up overviews before turning on the equipment! It'' s likewise vital not to hurry due to the fact that also minor mistakes can lead to significant injury or damages to the material being dealt with.

Moreover, correct upkeep ought to be done consistently in order for saws as well as cutting makers to remain practical and secure for use with time. This consists of cleansing dirt off components after each usage session as well looking for indicators of wear such as plain blades which require replacing quickly! Also oil should be used regularly so that elements remain lubricated correctly; this will certainly help prolong its life expectancy drastically!

In conclusion, sawing and cutting machinery requires mindful attention in addition to correct safety techniques when handling them. In addition regular upkeep has to happen in order for them to continue functioning appropriately and also securely over time! With that said stated, these devices give amazing energy when run correctly; therefore they should never be taken too lightly!

Sawing and cutting machinery is a vital part of any type of toolbox. From saws to cutters, there are various sorts of sawing as well as cutting machinery that can make any work less complicated! There'' s the table saw which can easily cut through wood or various other products with precision. After that there'' s the jigsaw, perfect for making detailed cuts in products such as plywood. In addition, circular saws are fantastic for making fast, straight cuts crosswise on surfaces like lumber. (Remember: safety initially!)

Not to be failed to remember are band saws which stand out at curving forms right into objects like furnishings pieces or music tools. Yet wait, there'' s more! Miter saws are available in handy when you require to make angled cuts in trim job or crown molding. As well as let’& rsquo; s not leave out hacksaws; they may seem straightforward but they ' re crucial for puncturing steels like

steel! Wow! In addition, one must additionally understand about routers as well as their capability to carve out designs from timber or plastic - a skill all its own indeed! Lastly don'' t forget plasma cutters; these effective devices can effortlessly slice through metal plates promptly and properly.

Finally, it’& rsquo; s clear that there & rsquo; s an array of various sorts of sawing and cutting machinery readily available that array from small hand-held ones to bigger electric ones –-- each designed with a certain kind of job in mind. Purchasing the best sort of tools will certainly conserve time and money - specifically when it comes to DIY projects around your home!

Benefits as well as negative aspects of sawing & & cutting machinery are plentiful! Using such makers supplies a variety of benefits, yet there can be some downsides too.

One significant benefit is that these tools provide a safe and efficient method to reduce materials. They are developed with security functions like guards and shields, making them a lot less likely to trigger injury than hand-operated saws or blades. Additionally, they can quickly as well as properly make cuts that would take a long period of time to finish by hand. All this saves money and time for firms or people that require to get work carried out in a timely way.

On the other hand, there are some negative aspects related to sawing & & cutting machinery. Initially, these devices need specialized training in order to run them safely and appropriately. This suggests extra costs for employers in regards to training new staff members or maintaining existing ones up-to-date on the most recent methods. Secondly, these machines can frequently be rather loud, which can be turbulent for those functioning near them or living nearby. Lastly, if not preserved appropriately they might not execute ideally - leading to low quality cuts which can lead to costly blunders!

Despite the potential downsides though, making use of sawing & & cutting machinery can still be valuable for many people if made use of appropriately and safely whatsoever times. Its advantages much outweigh its negatives; providing an effective way to get work done quickly as well as efficiently without running the risk of injury or loss of home from human error. So if you'' re searching for an effective method to reduce worldly after that take into consideration buying one of these machines –-- it just could be worth your while!

Safety and security is a vital aspect to think about when utilizing sawing and also cutting machinery. It (is) essential that drivers comprehend all safety preventative measures prior to utilizing any type of sort of saw or cutter. First, constantly ensure the area is clear of any debris or challenges which may get in the way of usage. Furthermore, never ever operate these makers without appropriate safety tools such as safety glasses, gloves as well as hearing protection. Additionally, double check that all blades are sharp and in good problem; plain blades can create kickbacks which could result in serious injury!

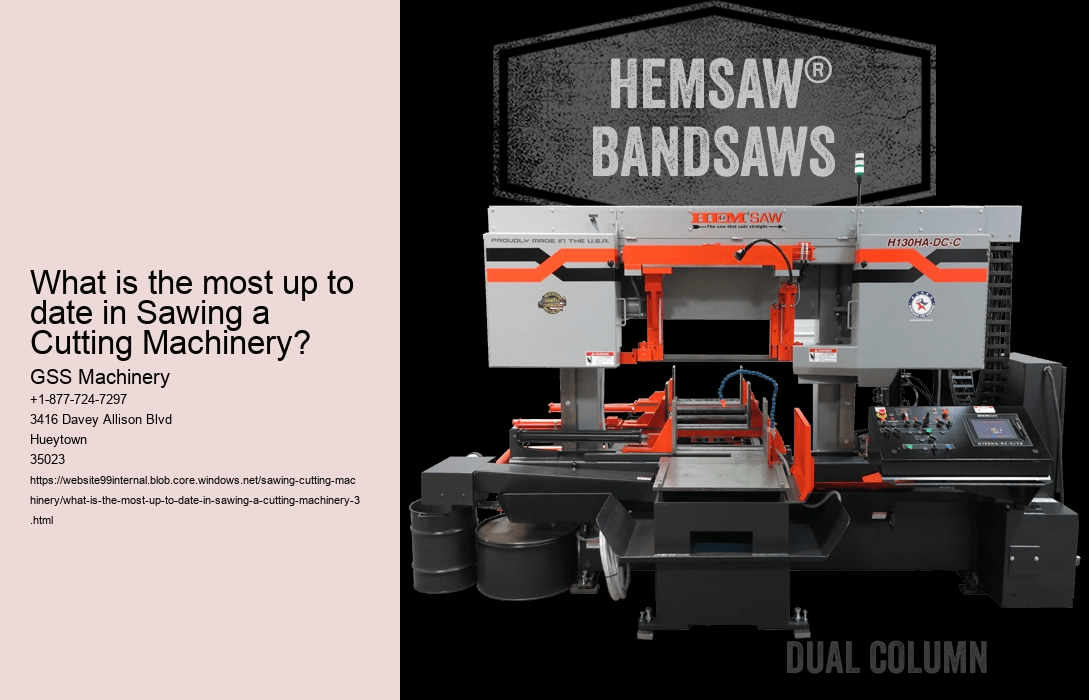

Additionally, make certain you have a company hold on the maker at all times; as well as do not attempt to cut products larger than what the equipment was created for. In addition, be sure you understand where your hands are located in any way times while running the machinery and keep them away from moving components. Let GSS Machinery elevate your metal fabrication processes with our state-of-the-art Sawing & Cutting Machinery . Contact us today to learn more about our offerings and discover how we can help you achieve unparalleled precision and efficiency in your cutting operations.. Finally, constantly check out and adhere to all directions offered by the producer before using saws or cutters.(Further,)It'' s additionally useful to take a class on fundamental security treatments prior to starting collaborate with these equipments.

In conclusion, it is necessary that anyone operating saws and cutting machinery takes necessary actions to guarantee their own security along with those around them. With correct expertise and also complying with suitable guidelines crashes can be protected against!

Upkeep pointers for sawing and cutting machinery is necessary to maintain these makers running smoothly. It'' s essential to regularly clean (machinery) and also lubricate parts, as this will reduce deterioration on the tools. Moreover, check blades for any type of damage or monotony and also change them when required! Don'' t neglect to change tension on belts as well as chains as needed; or else, they can trigger undue pressure on the electric motor. Additionally, it'' s an excellent idea to check all nuts, screws, screws, etc, for tightness-- loose bolts can cause malfunctions in the machine. Ultimately, make sure to alter out fluids such as engine oil or hydraulic fluid at ideal intervals in order on the other hand(?), preserve peak performance of your sawing & & cutting machinery!

The very best method to make certain that you'' re adhering to appropriate upkeep methods is by having actually a plan set up beforehand. Make a list of what requires to be done periodically and persevere! This'' ll permit you to easily track when jobs require attending; plus it'' ll save you time in the long run. Additionally consider using an app or software program that can aid advise you when precautionary upkeep is due on your sawing & & cutting machinery.

Finally, by following these upkeep suggestions for sawing & & cutting machinery we can lengthen its life expectancy while preventing costly repair services later on! With just a little effort now we can reap lots of incentives later-- it'' s definitely worth putting in the time to effectively take care of these indispensable devices.

Sawing as well as cutting machinery can be tricky to collaborate with. (It) can present a range of typical problems, such as defective components, used blades, or technological problems. Prospective services to these issues consist of frequently arranged maintenence, changing older get rid of more recent ones, or looking for specialist support.

Nonetheless, also after taking all the essential preventative measures, some troubles may still take place. In such cases, it'' s important not to stress! Instead require time to identify the issue and also evaluate your device'' s hands-on for possible solutions. It may also help to speak with specialists that can offer you with advice concerning what requires to be performed in order to obtain your equipment back up as well as running once again.

In addition, if you'' re experiencing power concerns when cutting materials, take into consideration utilizing alternative tools like jigsaws or hacksaws which don'' t call for a lot of electrical energy. In addition, make certain that the power outlet is working appropriately by inspecting the voltage and amperage setups; often wrong wiring can bring about electric breakdowns that could harm your sawing and cutting machinery.

In addition to this, always wear safety gear such as gloves or safety glasses when operating saws as well as various other gadgets for included security! And also keep in mind: never ever leave any kind of equipments unattended while they are running - crashes can take place in a split second! To summarise: normal upkeep as well as cautious use will go a lengthy method in staying clear of usual issues with sawing and also cutting machinery - one exclamation mark - so make certain you comply with ideal techniques at all times!

Sawing as well as cutting machinery is a vital part of numerous industrial operations. It can be utilized to cut through materials such as metal, timber, plastics or even paper! With the best sawing and cutting makers in position, it'' s possible to quickly and successfully complete jobs that would otherwise take a lot longer. (Nonetheless,) there are some safety factors to consider when using this sort of tools. Workers need to always follow security laws when running these equipments, as crashes can occur if ideal precautions aren'' t taken.

Additionally, it'' s essential to maintain the devices regularly in order to guarantee they remain in good working problem. This can include lubricating components, looking for damage on blades or various other elements and also clearing out any type of particles that may have obtained stuck inside the device. Doing so will certainly enable them to keep running smoothly whilst also expanding their life-span significantly!

Finally, sawing as well as cutting machinery is an invaluable possession for numerous markets however its use comes with certain dangers which have to be handled very carefully. By complying with all security directions closely and also carrying out normal upkeep checks, workers can get one of the most out of their sawing and also cutting devices without jeopardizing security or jeopardizing efficiency! Furthermore, services should invest in high quality machinery from reliable distributors for optimal results!

Sawing and also cutting machinery is a vital device for various industries. It (can) be used to make whatever from furniture and closets, to automobiles and aircrafts! Although it may appear challenging, there are plenty of resources offered to assist you start utilizing sawing as well as cutting machinery.

First of all, online video clips can give a superb aesthetic introduction into the fundamentals of running these machines. There are great deals of educational video clips readily available on YouTube that cover a range of subjects associated with sawing and cutting machinery. Additionally, a fast Google search will produce a multitude of resources such as discussion forums where knowledgeable customers can supply pointers or respond to questions concerning how ideal to make use of these devices.

Additionally, there are numerous trade magazines dedicated exclusively to supplying information on saws and also cutters. These magazines have short articles with comprehensive guidelines on maintenance and safety precautions, in addition to attribute tales highlighting brand-new products or industry patterns. Subscribing to them would certainly be a terrific way for a person just getting started with sawing and cutting machinery to stay up-to-date on the latest advancements worldwide of woodworking as well as metalworking.

Ultimately, speaking straight with professionals in one'' s location that collaborate with these devices consistently might verify vital in aiding one find out more about them. Lots of local equipment stores or lumberyards will certainly have employees that recognize specifically just how these tools function best, so they ought to have the ability to offer some useful insights right into their operation! Furthermore, attending a workshop or workshop concentrated especially on saws and also cutters may likewise be helpful for those searching for more advanced guideline in this field.

To conclude, there are numerous resources readily available that can help any person simply starting out utilizing sawing as well as cutting equipments - from online videos to trade publications - so don'' t allowed intimidation prevent you from benefiting from all these devices need to use!

Carbon tool steel. Cemented carbide. Ceramic tool. Diamond tool.

Metal cutting machines include lathes, milling machines, boring machines, grinding machines, machining centers, etc.

Modern domestic machines are also capable of working with a wide variety of materials and have a diverse range in terms their functionality. Manual sewing machine. ... 1.2 Sewing machines with treadles. 1.3 Domestic mechanical sewing machine. ... 1.4 Domestic electronic sewing machine.

The cutting tool is the one that shears the excess material off of the workpiece. Machine tool mounts the tool, the workpiece and any other accessories rigidly and imparts the intended motions.

What are the 10 best craft cutting tools? Cutting Machine. Cutting Machine Amazon. Amazon. Guillotine Paper Cutter. SCHUBphoto / Getty Images. ... 3 of 10. Rotating Paper Cutter. Amazon. Amazon. Rotary Cutter. ... 05 out of 10. Hobby Knife. Craft Knife. Craft Knife. Craft Knife. Cutting Mat. Cutting Mat. Stamp Punch. Stamp Punch.