Kingsland

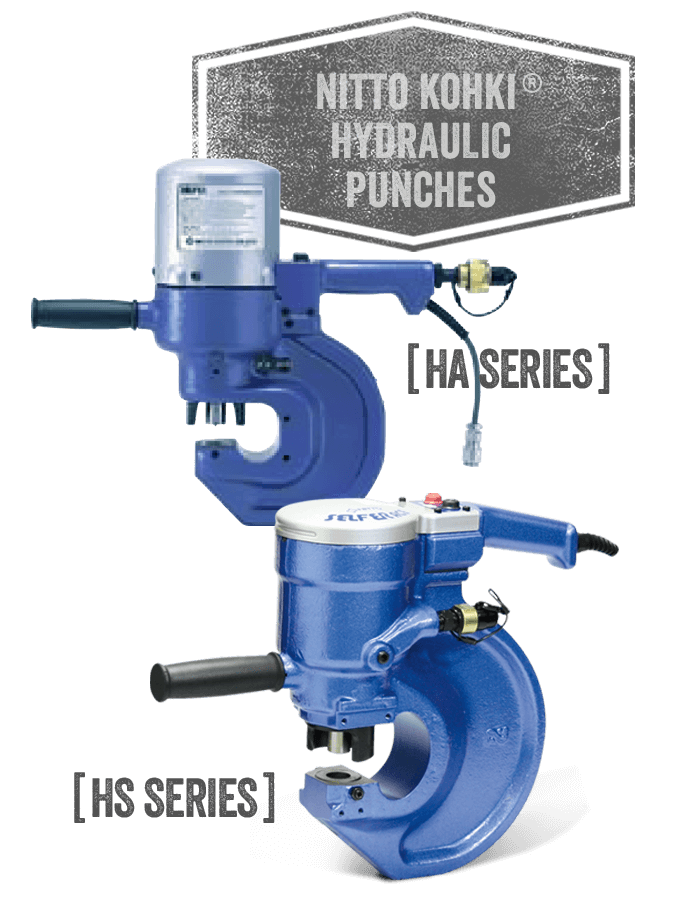

Portable double-acting hydraulic punches can process a diverse range of unique shapes, regular, oblong punches, and dies.

Quick mold changes, easy to use tools that are quick and easy to adjust. This significantly reduces the time it takes for modifications.