How did iron workers not fall

The Piranha/Whitney combination has a consistent ROI that beats all other laser technology, including plasma machines and laser technology to cut thicker parts more quickly. Our Punch Plasma Combination puts more parts on floor in steel and stainless steel than any other process.

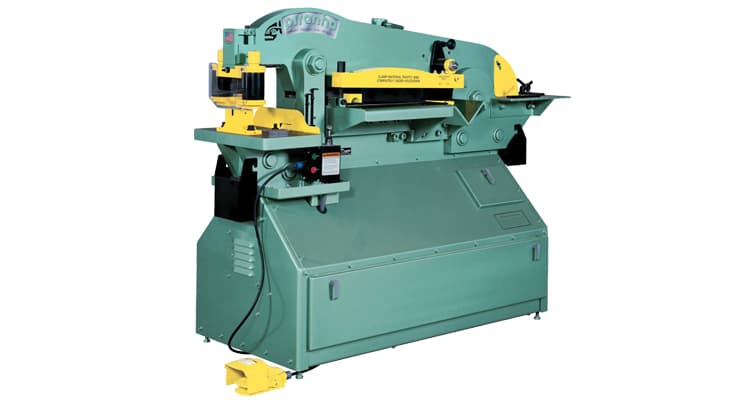

Our line of metal fabrication machinery will allow you to produce the highest quality products and maximize your profits. Piranha solutions offer fiber LASERs as well as punch-plasma combination and machines, laser cutting machines, heavy duty hydraulic bending rolls for ironworkers, ironworkers, press brakes and plasma tables.