What is iron work

Piranha ironworker machines give metal fabricators outstanding quality, innovative features, and range from 50 to 140 tons. Every Piranha ironworker provides quality work, savings in machine set-up time, versatility through a wide range of tooling, and superior factory engineering and support. Piranha Single Operator Ironworker machines are capable of performing most applications. However, when two simultaneous operations are required (e.g. punching and notching), a dual operator ironworker machine fits the bill.

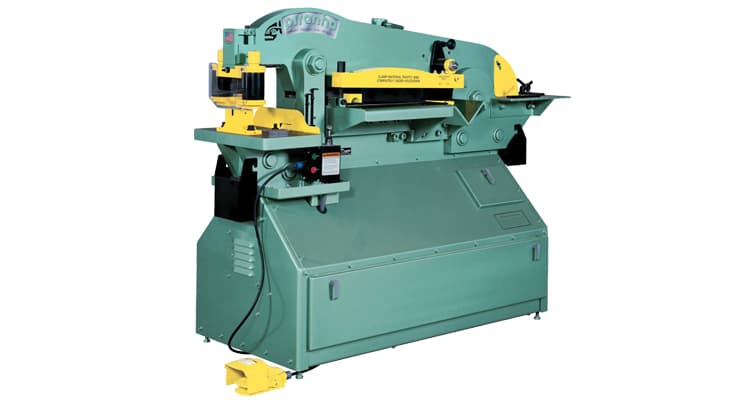

The Dual Operator Piranha PII 140 allows simultaneous operation at both the punch station as well as shear/copper notcher stations. This ironworker is the most powerful on the market and provides enough punching force to handle any application. It also has dual operators which makes it one of most productive.