Cnc Plasma Cutter Business Ideas

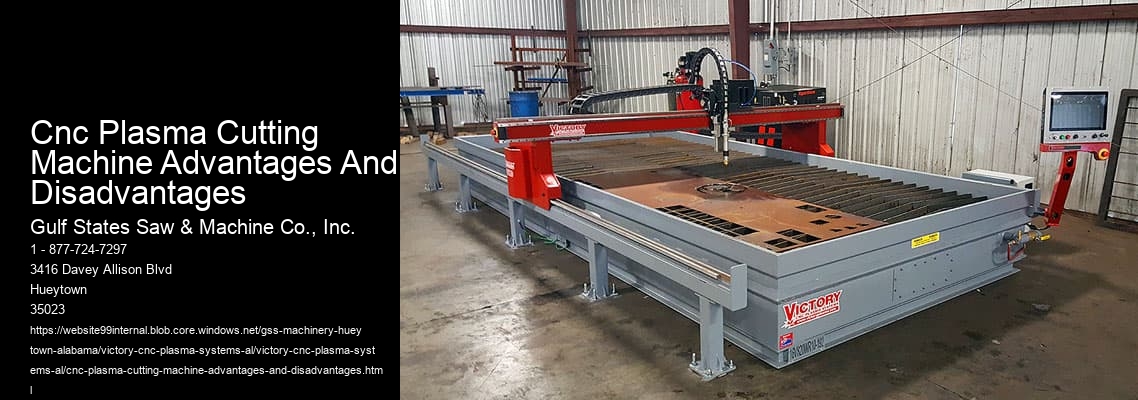

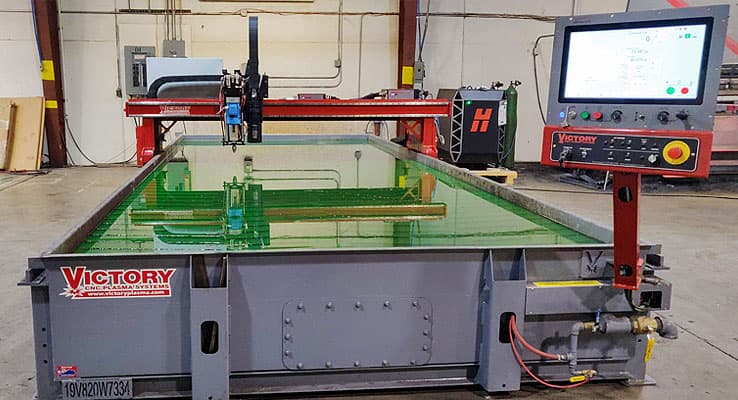

Victory CNC Plasma Systems is an original equipment manufacturer (OEM) of industrial CNC plasma cutting systems. We proudly build all our CNC plasma systems here in the US and we support everything we sell.

Unitized systems have cutting areas ranging from 5'x10" to 8'x20". The gantry system can be customized to fit any size up to 20'x 100'. AutoGas, pipe-cutting, oxy-fuel-cutting, drilling, full contour 5-axis Plasma Bevel and straight-line Plasma Bevel are all options.