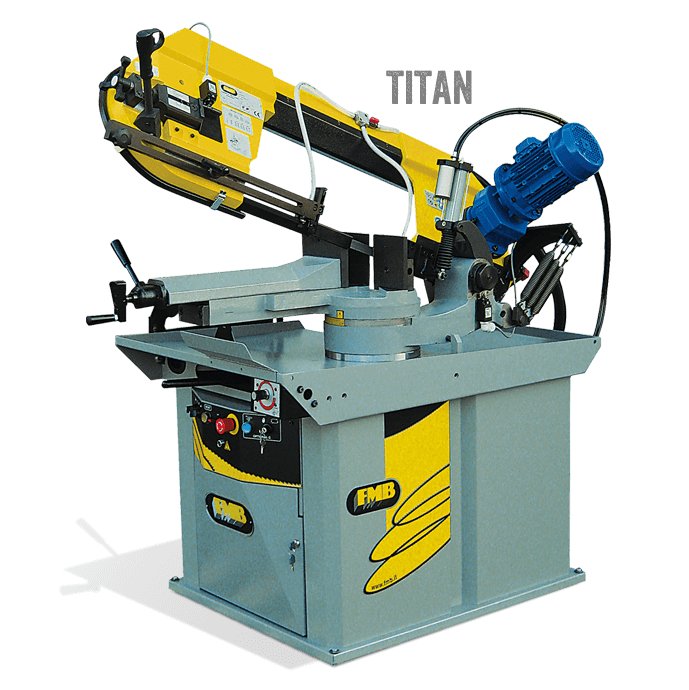

Manual Band Saws Details

Manual Band Saw 60

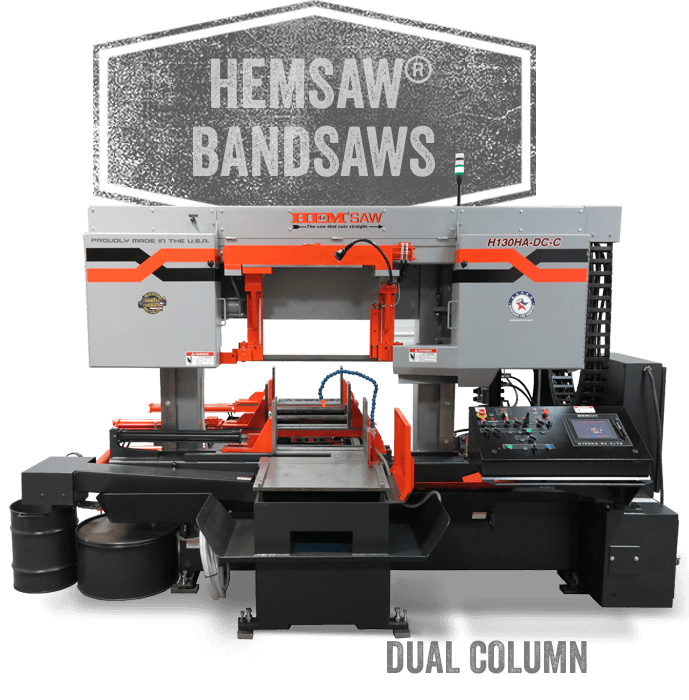

Voortman is a leading manufacturer of high-quality industrial-grade bandsaws that can be used in workshops.

Most band saws are used for woodworking. You can use them for lumbering or metalworking.