Manual Band Saws Impact Fees

Manual Band Saws Leather

They had to face problems due to the inability of existing technology to create long-lasting, durable blades.

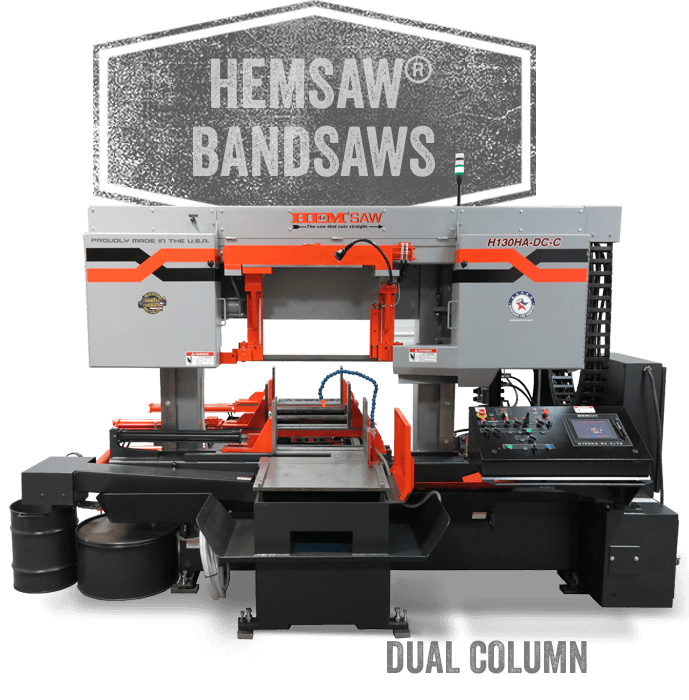

First, the saw is difficult to adjust. It can be difficult to adjust the alignment and expandable worktable as well as the tensioning belt. This saw is too heavy for anyone to carry.