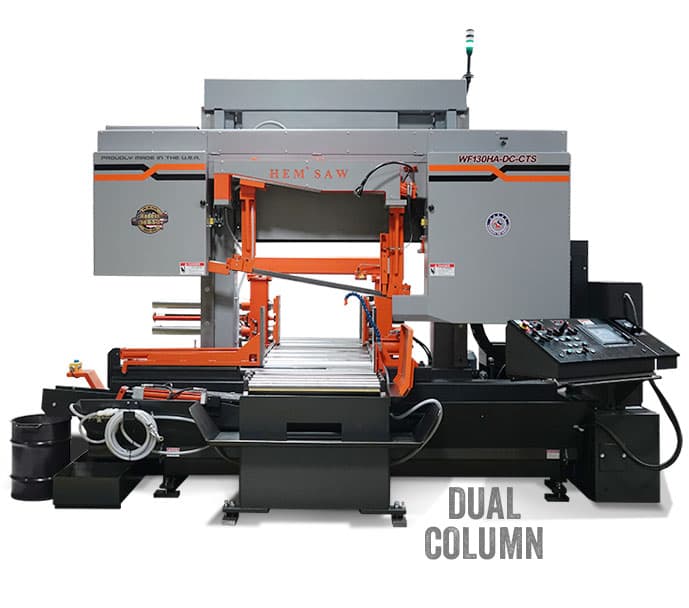

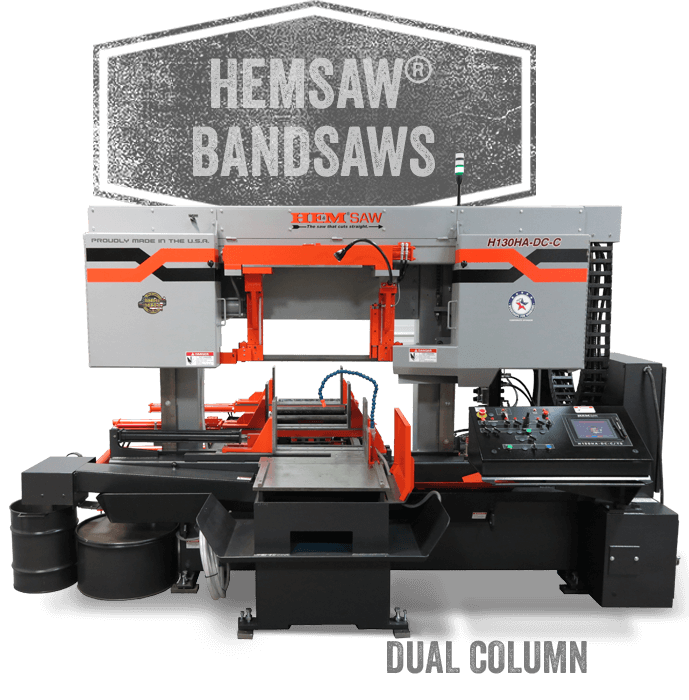

Cnc Band Saws

Manual Band Saws Stark

Just like most saws, a blade with smaller teeth is better for cutting metal. You will need a larger blade and fewer teeth if you are cutting wood.

Another thing we like about this saw are the easy-to-use tracking adjustments. The warranty lasts for five years.