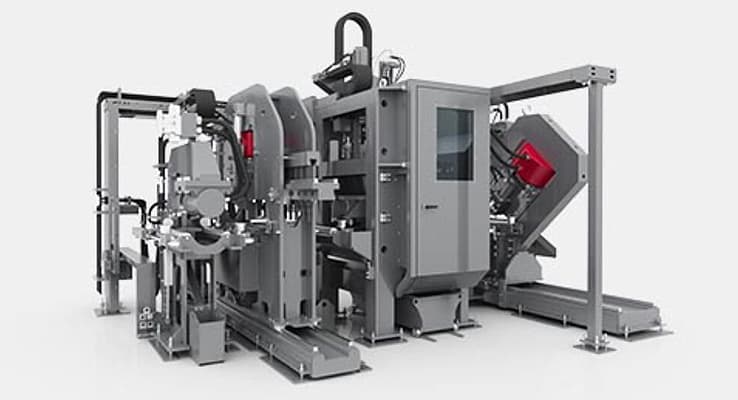

Structural Fabrication Machinery Houston

Gulf States Saw & Machine Co., Inc. owns the largest saw-blade shop in the southeast. Our supply catalog has over 50,000 products that we can offer our customers. Our clients are just as important to us as massive sales. We make it a priority to take care of them 24/7, 365.