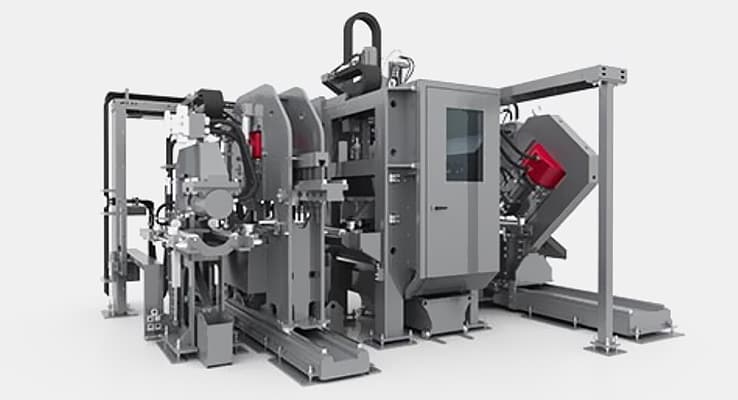

Plate Processing Machine

Our team has years of experience in many industries and can help any business, large or small, with the use the most recent technology and equipment. We can design, specify and install any type of machine.

Our team brings years of experience and knowledge to many industries. With a wide range of technology, we can help anyone, small or large, with the best technology and equipment. We can design and build any type of machine as well as service it.

Gulf States Saw & Machine Company specializes in robotic welding. Other industrial applications of Robotics include Machine Tending and Material Handling. Atlanta Technology Center is the headquarters of Gulf States Saw & Machine Company. We also provide training and maintenance for customers in Dallas. We have continuously increased our technical staff, including application and service engineers, welding engineers and application engineers.

Our team has years of experience in many industries and can help any business, large or small, with the use the most recent technology and equipment. We can design, specify and install any type of machine.

Gulf States Saw & Machine Company has modular Fusion Arc-welding cells, in house training classes, and a large inventory of consumables. Welding and application engineers are trained to teach the classes.

Gulf States Saw & Machine Co. recognizes that every fabricator has a different need. We also understand the nature and processes of each task. We chose only the best structural fabrication machines that would meet your specific needs. No matter your preference range, we have you covered

Gulf States Saw & Machine Company features modular Fusion Arc welding cells, in-house training classes, and a large supply of consumables. These classes can be taught by both welders or application engineers.

Gulf States Saw & Machine Company specializes robotic welding. Robotics can also be applied to other industrial tasks like Material Handling or Machine Tending. Atlanta Technology Center hosts the headquarters of Gulf States Saw & Machine Company. We also offer training and system maintenance to Dallas customers. We have continually increased our technical staff to include service and application engineers as well welding engineers and application experts.

Structural fabrication refers to the cutting, bending, and assembling of steel to create different products.

Structural steel fabrication involves cutting, bending and welding steel to make a structure. Unlike various types of welding in which steel alloy is repaired or strengthened, steel fabrication is when pieces of steel are put together to form different structures that are usually of predefined sizes and shapes.

And while different metal fabrication companies use different techniques, most rely on three basic processes: cutting, bending and assembling.