What is a spandrel girder

Voortman CNC Beam Cambering has an all-steel frame, horizontal piston pusher, and memory settings. This guarantees reliable output for all of your projects. The touchscreen operator panel makes it easy to use the V2000.

You can be sure of a reliable and consistent result every time.

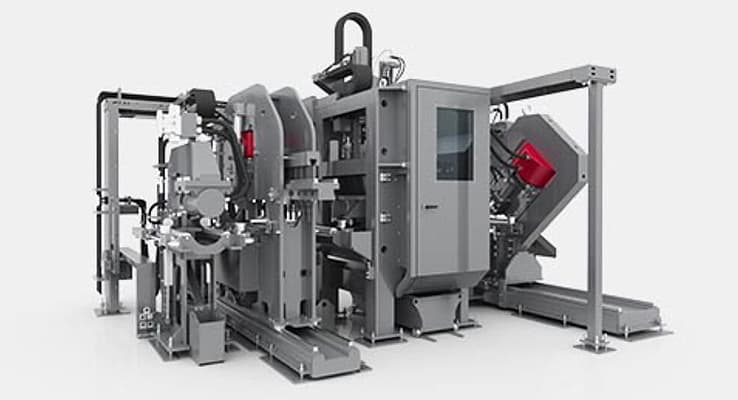

Voortman V2000 Beam Cambering & Straightening Machine. Every time you use the V2000 Beam Cambering & Straightening Machine, you can expect a consistent and reliable result.

Voortman CNC Beam Cambering has an all-steel frame, horizontal piston pusher, and memory settings. This guarantees reliable output for all of your projects. The touchscreen operator panel makes it easy to use the V2000.

Gulf States Saw & Machine Co. employs a rigid, steel C-frame, horizontal pusher, and memory settingsin their production of Voortman CNC Beam Cambering. This ensures reliable output with all projects. Voortman CNC Beam Cambering features a touchscreen operator panel with easy-to-use functionality that makes using the V2000 simple.

Voortman CNC Beam Cambering features an aluminum C-frame and a horizontal piston pusher. It also has memory settings which ensure reliable output with every project. It also features a touchscreen operator panel that makes it easy to use the V2000.

Gulf States Saw & Machine Co. uses a C-frame made of steel and a horizontal pusher. Memory settings are used to produce Voortman CNC Beam Cambering. This assures reliable output on all projects. Voortman CNC Beam Cambering has a touchscreen operator panel. This makes it easy for you to use your V2000.

BENEFITS INCLUDE: Smart cambering and Accurate, Automated positioning, Hydraulic pusher, PLC controller, Remote control to mobility, Combine cambering using other Voortman devices

Cambering is the curving of a beam about the strong axis of the member, while, sweep applies to the curving of a member about the weaker axis. Cambering is typically performed by a steel fabricator after the member has been cut to length and punched or drilled.