What does pre cambered mean

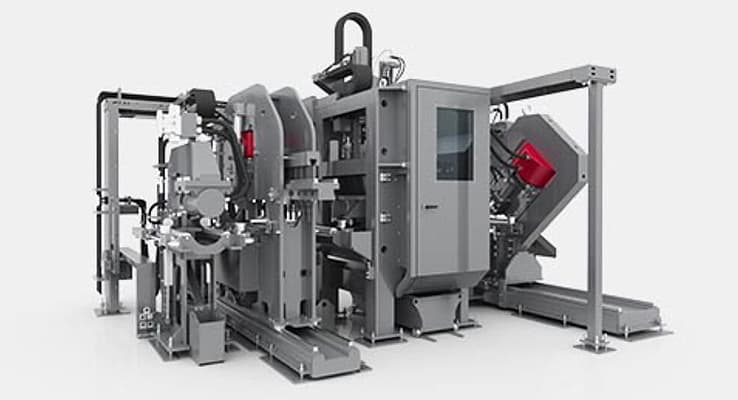

Voortman CNC Beam Cambering uses a rigid steel C frame, horizontal cylinder pusher, and memory settings to ensure reliable output for every project. The touchscreen operator panel makes it easy to operate the V2000. Voortman V2000 beam cambering and straightening machine produces consistent, reliable output every single time.