Fiber Laser Cutting Machine Youtube

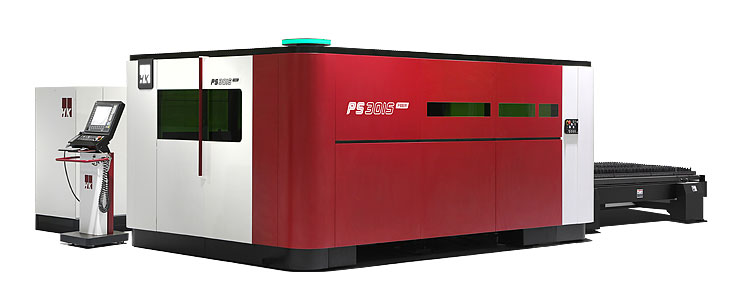

The industrial-grade maintenance-free laser cutting system has outstanding technical advantages, ultra-low power consumption, reduced operating costs, and repeatable and accurate laser positioning performance, which sets a new benchmark for the cutting of complex patterns and establishes a new standard for process quality inspection.

Next, turn the main switch on the control panel to turn on the main power. Turn the key switch at the control panel. This is specific to each laser and may not apply to others. After startup, the system will quote if all covers with safety circuit breakers have been closed. The machine will turn on once the table has moved all the way down, while the pro-laser head moves to the zero position (located at the upper left corner). The machine is now ready for operation when the LED light flashes steadily and slowly, and there is a sound.