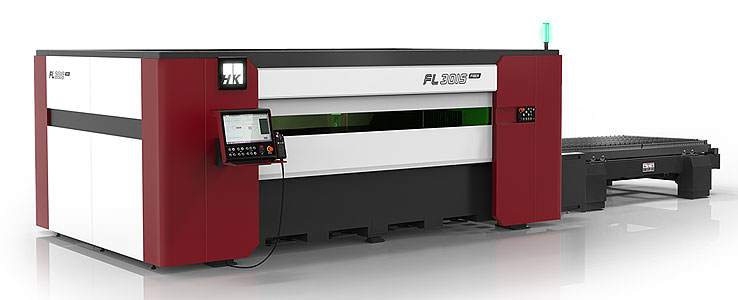

An entry-level laser cutler costs $2,600-8,800 and includes an 80W CO2 optical tube. This laser tube is ideal for beginners, enthusiasts, hobbyists, and small businesses. But high-end laser cutters can cost up to 279,000.00, which includes a 12000W fiber laser power supply that can be used for industrial metal fabrication.

Whether sublimation cutting, flame-cutting, or fusion cutting is used, because of a laser beam�s narrow focus, the width of the cut, or kerf width, is very small compared with other thermal cutting processes. Thus, minimum material is melted, and the laser energy is used very efficiently. The material�s heat input is relatively low so that even small geometries can be cut.