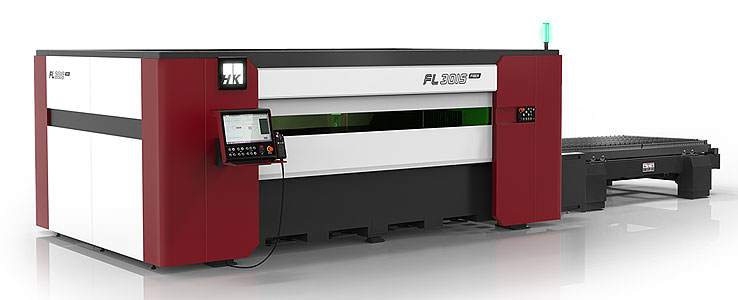

Power Systems Laser Cutting

The staff must be present on the site to inspect the equipment's cutting condition. If there is an emergency they should press the brake button quickly.

A fiber laser generator is the best option if you need to cut sheet and tube metal. This includes well-respected brands like Raycus, Raycus and MAX. You can use a CO2 laser tube to engrave or cut wood, acrylic leather, fabric and leather. It includes some of the most renowned brands like RECI and YONGLI.