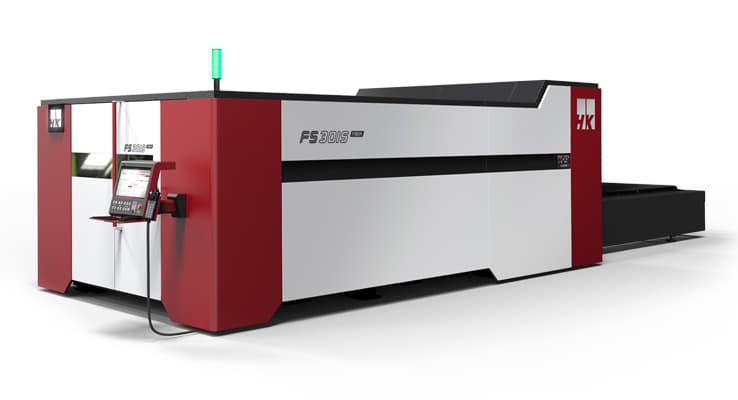

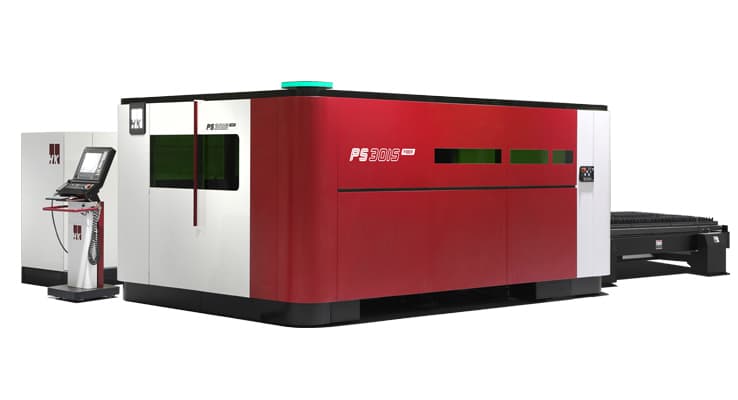

Precision Fabrication Machinery Valley Mills Tx

Our mission is to continue to develop production technology, making it more efficient, precise and future-proof. Our innovations are used in nearly every industry sector and we are the market leaders in lasers and machine tools for industrial manufacturing. Our software solutions open the door to the Smart Factory and allow us to implement high-tech industrial electronics processes.

Our experience includes many robotics applications in the life sciences, including assembly, material handling, and primary packaging.