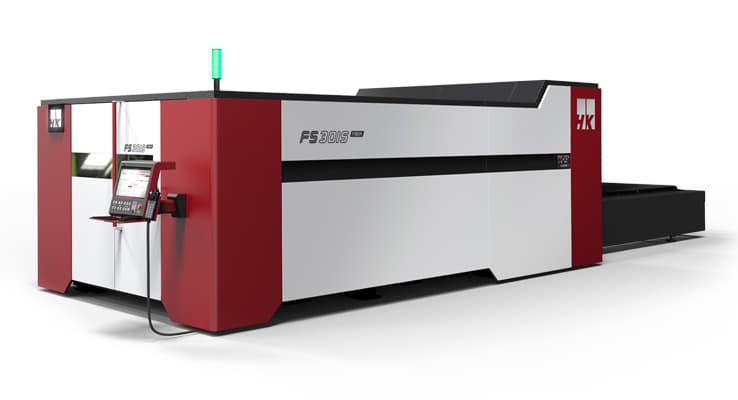

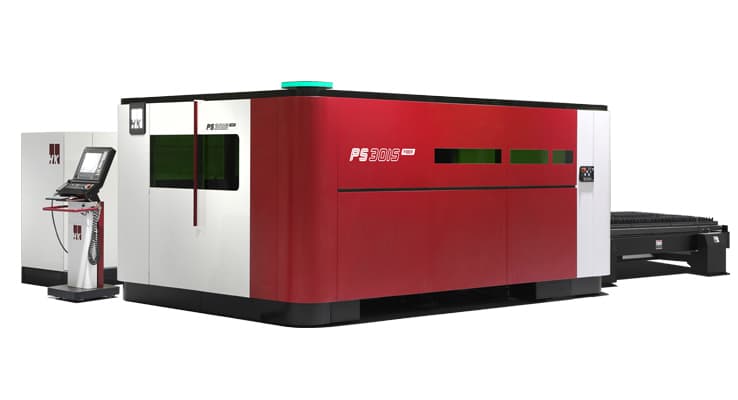

Engineering Stock

GSS Machinery takes pride in our unique processing capabilities. We utilize the latest software, tooling, machining and other technologies. This allows us to keep our promises.

Handy Stands can be used in schools, offices, retail stores, and other public places. With the convenience of a handheld hand sanitizer, you can keep those around you safe.