Precision Fabrication Machinery Of Texas

We assist businesses in increasing efficiency, productivity and quality so they can compete in global markets.

GSS Machinery is able to handle complex vacuum assemblies and in-vacuum mechatronics projects.

Finishing machines are used to give the exterior of your metal production a beautiful finish. Deburring, rounding the edges, and other techniques are frequently used to accomplish this. Equipment calibration impacts production speed and finishing capability; hence, specific machines are more suited to a certain project than others.

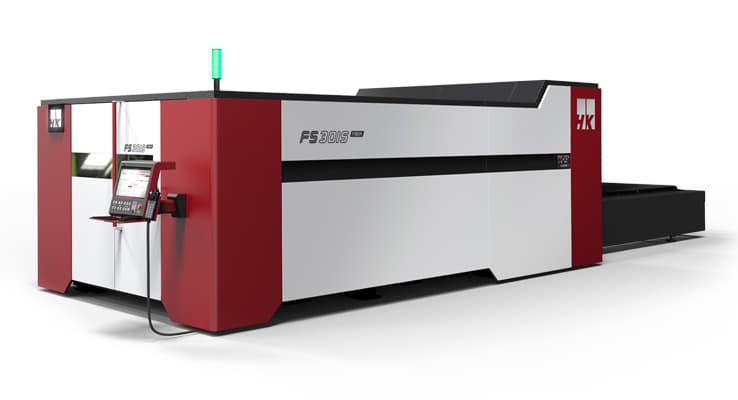

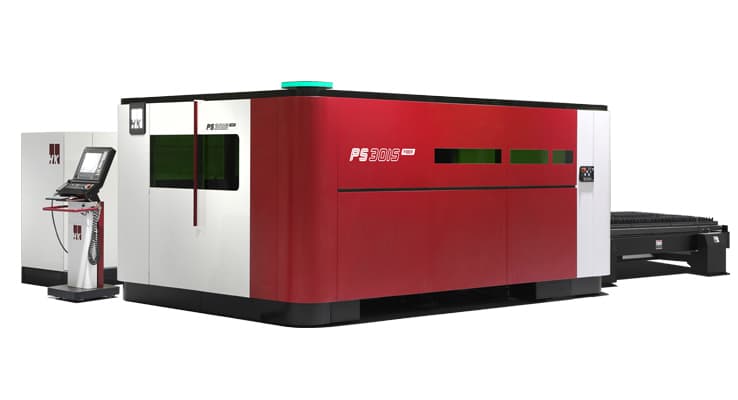

The CNC laser metal cutting system is fast, efficient, high-quality and precise. This makes it an ideal metalworking buddy. It can cut steel plates and tubes/pipes made out of stainless steel and carbon steel.

From idea conception through prototype, beta build and production, GSS Machinery is ready to take on your product development requirements.

You can give your metal productions a stunning exterior finish with finishing machines. You can do this by using a variety of techniques, including deburring, cutting, and rounding. Equipment calibration has an impact on production speed, finishing ability, and so certain machines are more suitable for a specific project than others.

We assist businesses in increasing efficiency, productivity and quality so they can compete in global markets.

GSS Machinery is able to handle complex vacuum assemblies and in-vacuum mechatronics projects.

As a medical device manufacturer, the products you make are crucial for delivering successful patient care. We can help.

Gulf States Saw & Machine Co. is able to handle a variety sheet metal fabrication projects. To guarantee a high-quality product, we work according to your requirements. We are experts in many metal fabrication services such as:

Our mission is to continue to develop production technology, making it more efficient, precise and future-proof. Our innovations are used in nearly every industry sector and we are the market leaders in lasers and machine tools for industrial manufacturing. Our software solutions open the door to the Smart Factory and allow us to implement high-tech industrial electronics processes.

Our experience includes many robotics applications in the life sciences, including assembly, material handling, and primary packaging.

Gulf States Saw & Machine Co. handles a variety of sheet metal fabrication projects. We work to your exacting standards to ensure a quality product. We specialize in a number of metal fabrication services including:

You don't have to worry about back reflections damaging your laser cutter. These fiber laser systems are easier to maintain and cost less to operate.

Gulf States Saw & Machine Co. supplies high-purity nitrogen gas generators that are both PSA and Membrane. From our Hueytwon, Alabama location, we have been manufacturing reliable systems all over the world since 1999. Our products have been used in many industrial applications worldwide, thanks to our extensive experience in nitrogen generation. Our engineers provide state-of-the-art solutions and products to clients, no matter if they are on the shop floor or at the oil platform.

Healthcare devices must always be built with skill and precision to provide quality patient care.

Laser Cutting Process Drawbacks

When compared to other techniques, laser cutting requires a high power consumption.

The laser beam is extremely delicate to handle.

If the laser beam comes into contact with human workers, it is hazardous.

Laser cutting is still unable to cut thick metals.

High-wattage laser cutting machines, on the other hand, are typically much more expensive than entry-level models. Some laser cutter models range in price from $4,000 to $15,000.

The Best Laser Cutter for Extensive Designing

Orion Motor Tech Upgraded Laser Engraver. This spiffy-looking machine is one of the best on the market right now. ...

Beamo 30W Desktop Laser Cutter. ...

Ten-High 4060 Laser Cutting Machine. ...

Dremel LC40-03 Laser Cutter. ...

Orion Motor Tech Laser Engraver Cutter.