Single-acting Cylinders

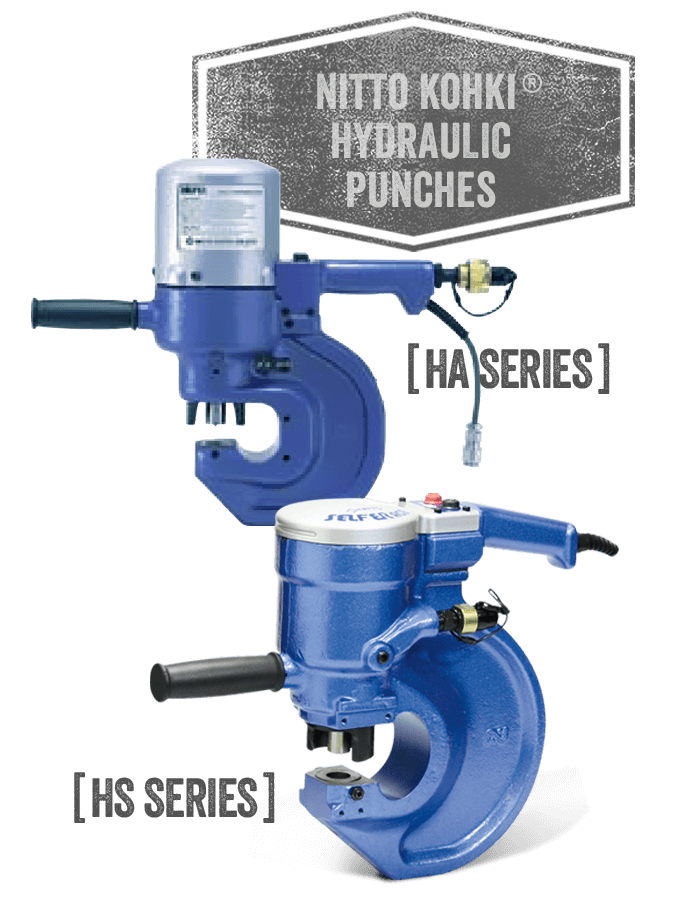

Many industries use hydraulic punches. They are time-saving, have excellent cycle times, can be used in a variety of industries, and are simple to use.

Hydraulic punches that can be used in portable double-acting configurations are able to process a variety of shapes, including oblong and regular punches.