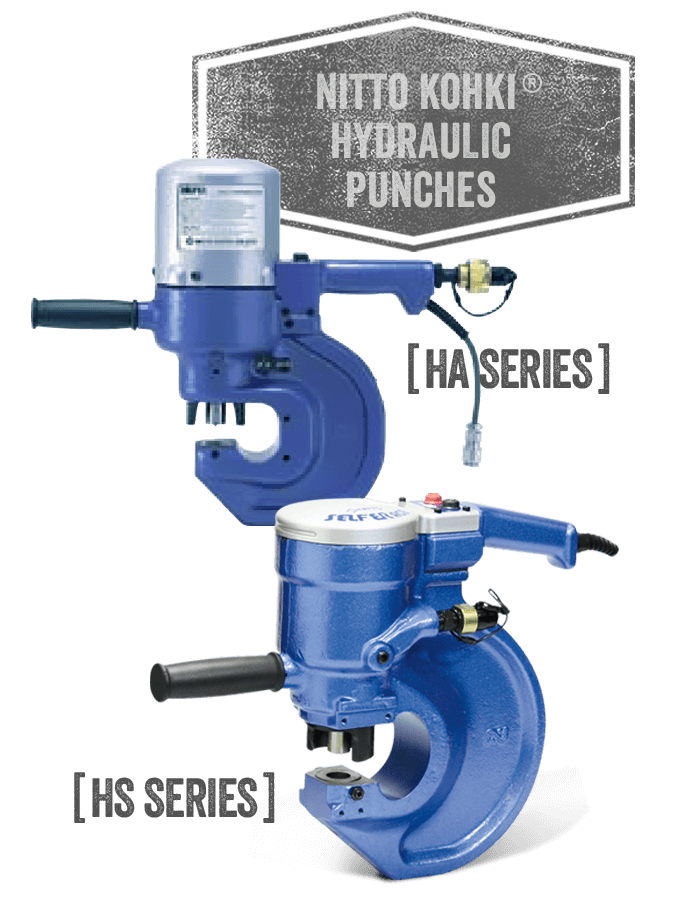

Single Acting Hydraulic Punches

GSS Machinery has a vast selection of machines that can be used for your specific operations. We are able to sell our machines in different countries. Our reception is excellent. Your location doesn't really matter when it is time for delivery. Our clients are testament to the strength and endurance of our machines.

You've found the best portable single-acting hydraulic punch. With accuracy and practicality being top priorities, this is the place for you. Our punches are suitable for all applications. For any technical questions or recommendations, please don't hesitate to contact us. We are happy to assist you with all your needs.