Single Acting Hydraulic Punches Raccoon

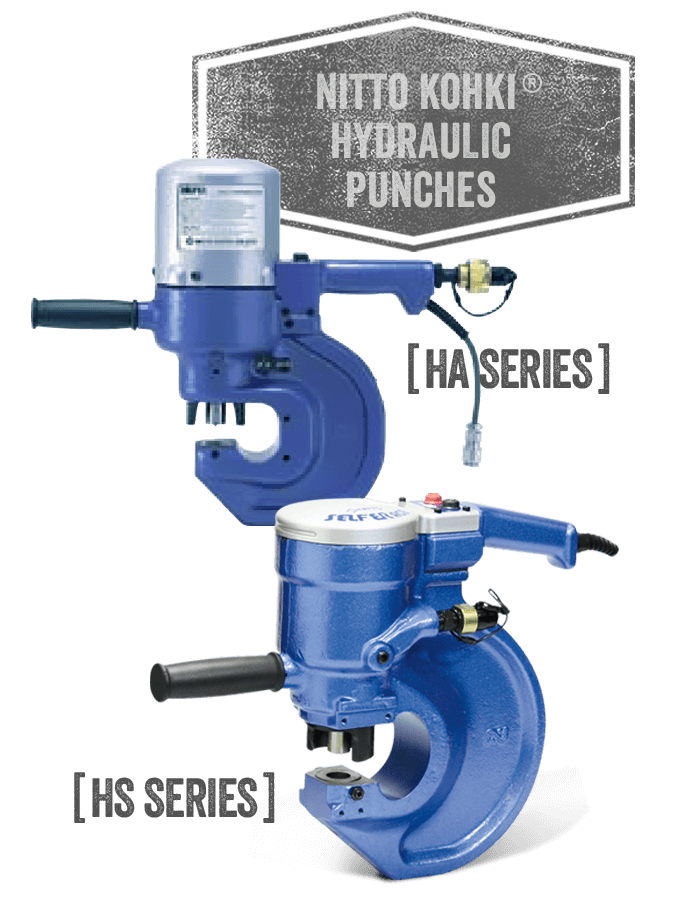

This machine features a dual-action model that reduces cycle times, and its compact design allows minimized material handling, which produces highly effective holes compared with other processes.

This hydraulic punch range is used in many industries such as utility pole cross arms (utility pole cross arm), electric tower crossarms, elevator bracket, air conditioning bracket, Zinc steel, guardrail, angle-steel shelf and many others.