What materials Cannot be cut with plasma

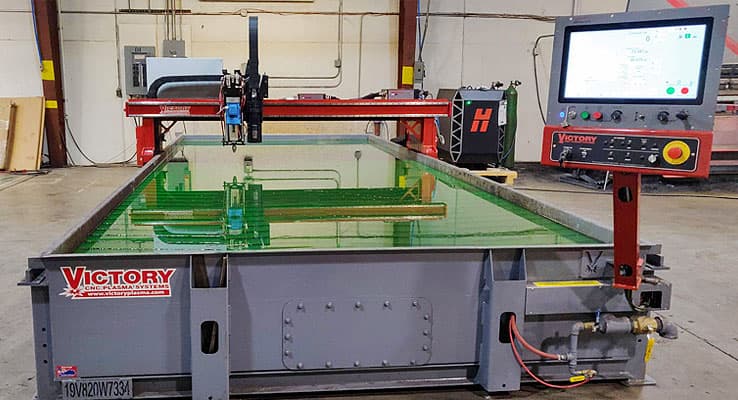

Victory Bridge CNC plasma systems feature a floor-mounted dual drive welded bridge system. This system rides over a downdraft, or water cutting platform and supports full sheets (3") of plate. Sizes range from 5'x10’ to 20’x 100'. These machines can be mounted on existing cutting tables or purchased cutting tables and are available without the cutting board. Victory will provide the drawings necessary to build work tables from scratch. The complete system is ready to use and includes all Hypertherm plasma components. This includes the bridge mounted EDGE Connect TC control, HPR or XPR plasm cutters, Autogas. True Hole, true hole, and plasma marking. Multiple oxy-fuel torches are available, including a 3/4hp and 3hp CNC Drill, multiple plasma cutters. The 16" outboard tube cutter is also included. Systems start at $189,000.

Victory CNC Plasma Systems (OEM) is an original equipment manufacturer of industrial CNC plasma cutting machines. All of our CNC Plasma Systems are proudly manufactured in the USA. We also support all products we sell. The unitized systems can be used to cut areas up to 5'x10' by 12'x40'. Gantry systems can also be purchased in sizes up to 20ft x 100ft. AutoGas, pipe-cutting, oxy-fuel-cutting, drilling, straight line bevel, and scribing are all options for CNC plasma systems.