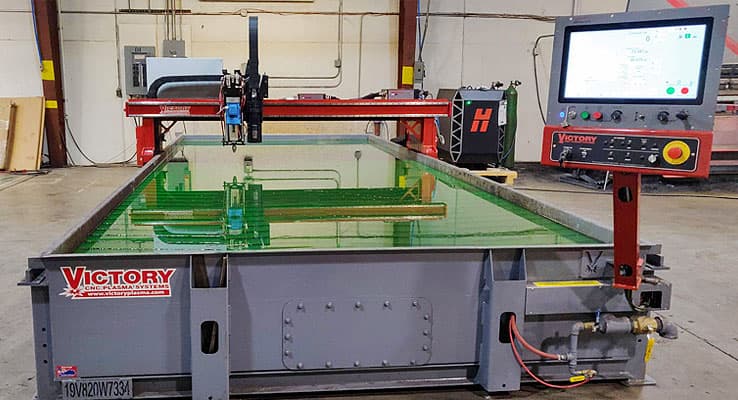

Victory Unitized CNC Plasma System is an excellent option for those who are looking to purchase an industrial plasma machine. This dual-sided drive system features a W4-13 frame with 3/16” plate downdraft or watercut bed that supports full sheets (2”) of all welded steel, Yaskawa and Yaskawa. It is available in sizes ranging from 5’ x 10’ to 8’ x 20’. This system is equipped with the EDGE Connect TC Controller and your choice from any of the Hypertherm liquid cooled plasma power supply options, such as HPR400, MAXPRO200 or XPR170 &300. Systems start at $129,000. ProNest, True Hole 3/4hp drill, an ox torch and SnapLoc straight -line bevel are just a few options.

Our CNC plasma systems can be turned-key and are fully functional. As standard equipment, they include the following: automatic torch height control, automatic torches collision protection, helical-planetary drive gear box, pneumatic pretensioning, emergency stop switches, and pneumatic pretensioning. Before shipment, our plasmas and controllers have been installed and tested. We install and ship complete systems ready for production, while other manufacturers attempt to finish their system at your factory floor.