Band Saw Alternative

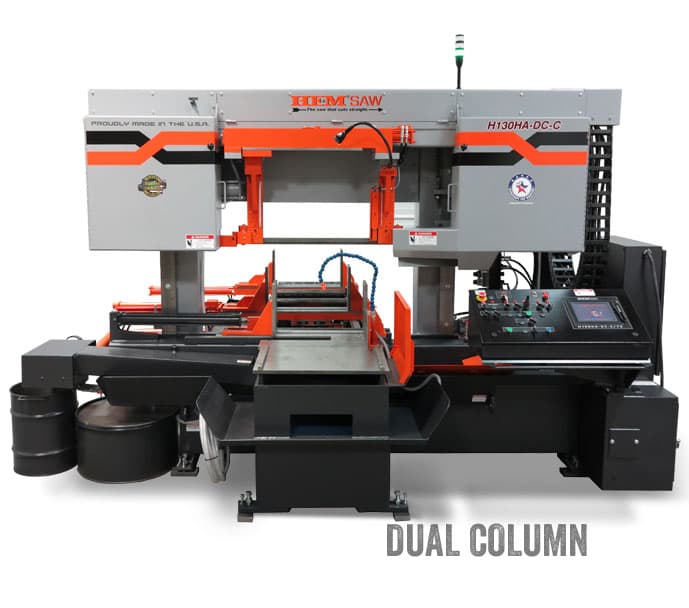

Machine

Band saws of high quality perform a wide range of precision woodwork better than any other machines in the workshop. My seventeen years of woodworking experience will help you find it.

Our circular saws offer precision, quality and value in cutting aluminum and bar stock. The aluminum uncut saw can be set up with semi-auto or auto feed systems. It cuts aluminum without raising burrs. Our CNC Cold Saws are the right choice if you require a saw that can feed multiple CNC machining centers or a forge. This option is a great investment because it can replace up to 4 production bandsaws with one machine.