Band Saw Blade Sharpener

Band Saw Jha

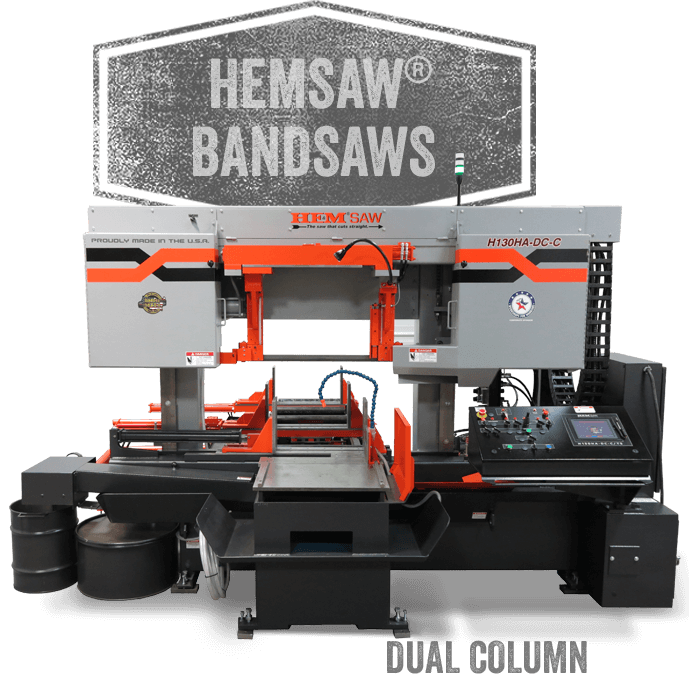

The loop blade rotates by turning between the idler, which is above the worktable, as well as the drive wheel which is below it.

The wheels are also made from heavy cast iron, which adds momentum to the blades and makes it easier to cut through difficult materials.