Band Saws Dewalt

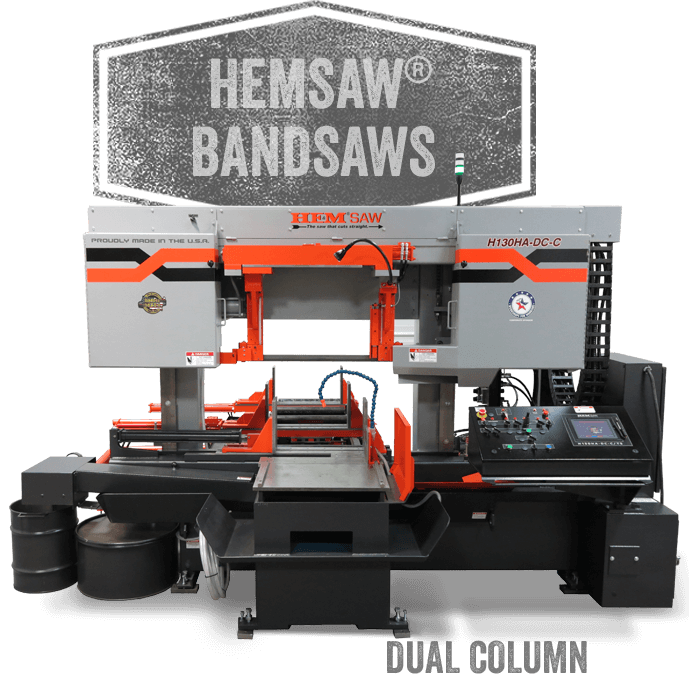

Band Saws For Cutting Metal

The wheels are also made out of heavy cast-iron, which gives the blades more momentum, making it easier and faster to cut through hard materials.

The table and frame are made of precision-ground, cast iron for a stable work surface that is vibration free.