Indiamart

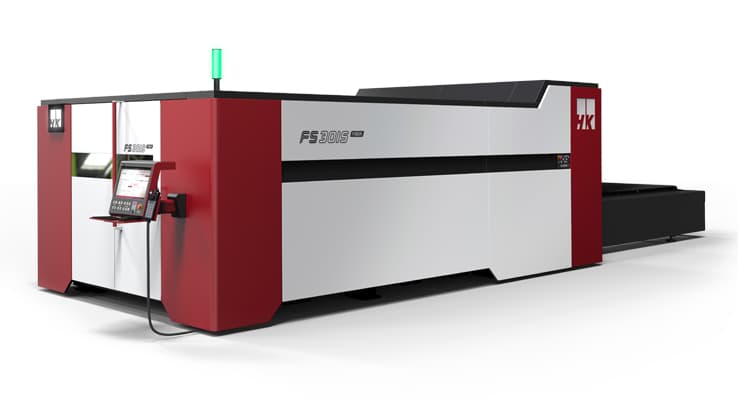

Laser metal cutting machine that is high-quality, accurate, quick, and efficient. It will be a great metalworking friend for all your cutting needs. You can use it to cut steel sheets/plates or tubes/pipes made from stainless steel, carbon, electric steel, galvanized and aluminum zinc plates, aluminum, aluminum alloys, titanium alloys, copper, brass and other metals.

Gulf States Saw & Machine Co. specializes is providing high-end precision fabricating machinery for metal fabrication in various industries. Our products are used by many metal fabrication industries such as aerospace and automotive.