Parata Systems

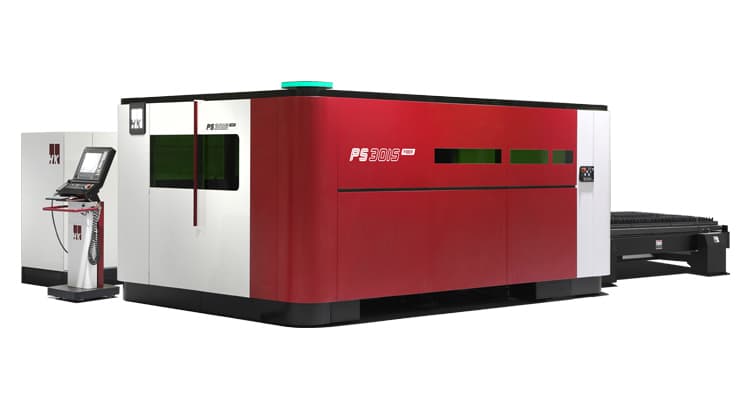

We have the capabilities to handle complex precision fabrication projects. If a process is not possible to support, we can refer to our established supply chain. Our primary focus is precision tube and plate fabrication. We can do it from half-inch to ten inches (0.25m). We can also handle any part that weighs more than 70,000 lbs. If we do not have the ability to support a process, our qualified supply chains will.

We have the ability to design and fabricate custom machinery that can be used for the production of sterile products within aseptic environments.