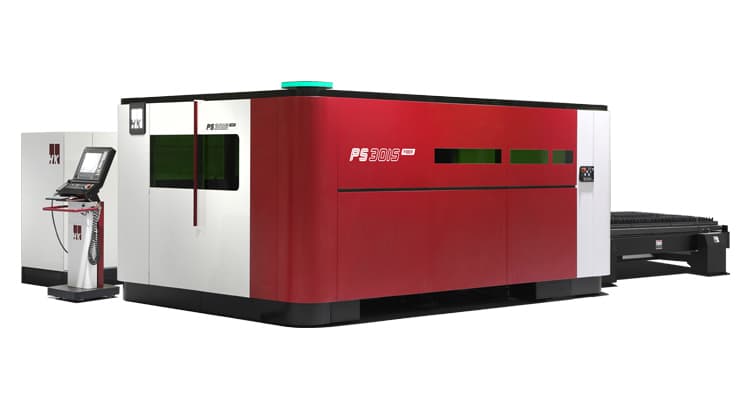

Machine

Trust and security are assured by our extensive knowledge in complex electromechanical parts.

Precision fab can be performed by thousands of shops. You can't just deliver high-quality parts on time if you want to be different. We are focused on customer service. We strive to deliver the best service, from quote to delivery. We send you a weekly report detailing what's happening on your part. We will be honest if we fall behind on your part. We won't always get it right. We will get it right. We are not your only source of information. Check out the feedback from our customers.