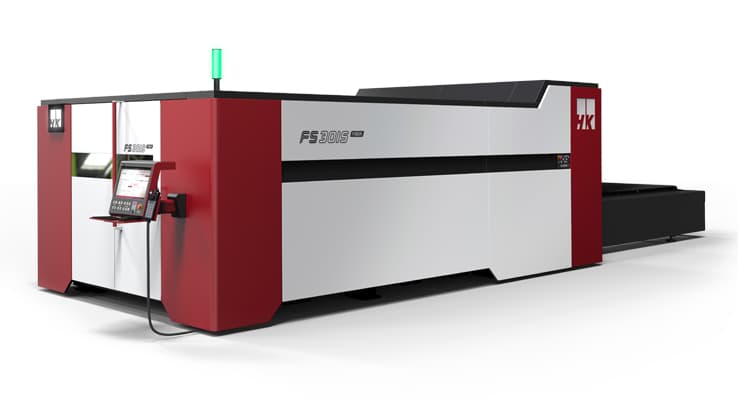

Machining

International Technologies, Inc., a distributor of the most technologically advanced metal fabrication machinery, is driven by customers. We pledge to work with you business to provide the most advanced metal fabricating equipment today, and to support each purchase for the entire life of your product.

We specialize in high-end equipment for high-end applications, including value-added integration of chambers with frames, internals, electro-mechanics, pneumatics, load-locks, and robotics and other complex components.