Customer

We have the capabilities to handle complex precision fabrication projects. If a process is not possible to support, we can refer to our established supply chain. Our primary focus is precision tube and plate fabrication. We can do it from half-inch to ten inches (0.25m). We can also handle any part that weighs more than 70,000 lbs. If we do not have the ability to support a process, our qualified supply chains will.

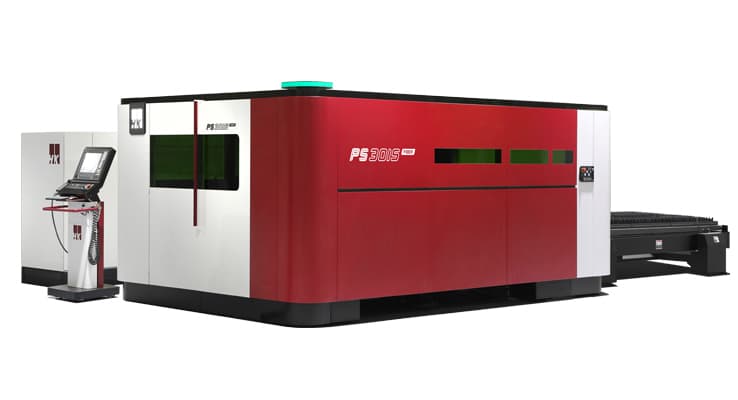

Gulf States Saw & Machine Co. offers custom welding and fabrication services. With our CNC capabilities, we can also add value to weldments and fabrications. Instead of sending the fabrication to one source and the machining to another, look to GSS Machinery for a complete turnkey experience.