Precision Fabrication Machinery Kent

We specialize in custom manufacturing sub-systems for healthcare equipment that is cGMP compliant.

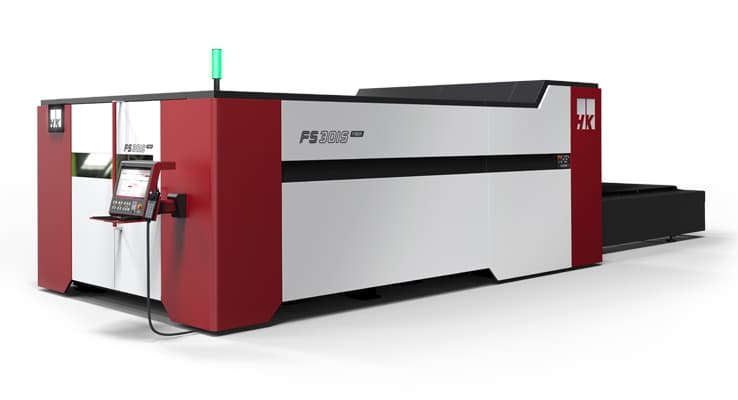

Testimonial - �I wanted to write and thank you personally for the excellent sales, installation and follow-up of our new Trumpf 2030 Fiber laser with Liftmaster shuttle. The whole system is working great. We enjoyed working with you and Eric during the purchase of this machine but even more then that we love the follow-up support we�ve received from both Gulf States Saw & Machine Co..�