Welders

We offer a wide range of services including build-to print for systems, equipment, and assemblies.

GSS Machinery has offered high-quality services in manufacturing, including pressure vessels which meet ASME safety requirements.

GSS Machinery is a pioneer in cGMP regulatory environments and offers unparalleled experience with particle accelerators and beam line equipment.

GSS Machinery understands that our customers are involved in high-stakes applications, from national security and research to health care. We strive to provide equipment, components, and custom fabrications that can withstand pressure. Our custom precision fabrication solutions are ideal for demanding industrial applications and research that require complex manufacturing.

Gulf States Saw & Machine Co. specializes as custom sheet metal fabricating. We are a machine shop located in Raleigh, NC. We specialize in tight tolerance parts for a wide variety of industries.

We can offer customers build-toprint services for any type of equipment or system.

We offer a wide range of services including build-to print for systems, equipment, and assemblies.

GSS Machinery has offered high-quality services in manufacturing, including pressure vessels which meet ASME safety requirements.

Auto-Sert Hardware Intection Presses are hydraulic-powered presses that can insert most major brands self-clinching nuts, standoffs, and studs into flat sheet metal assemblies.

Our five-axis large format machining and metal fabrication capabilities make us unique. They are used worldwide for lab research, semiconductors and solar products as well as medical equipment and other highly demanding applications.

GSS Machinery blends engineering and technical know-how to produce custom machinery prototypes as well as pilot plants and full production line.

Reliable automation solutions are essential for the manufacture of medical instruments and systems.

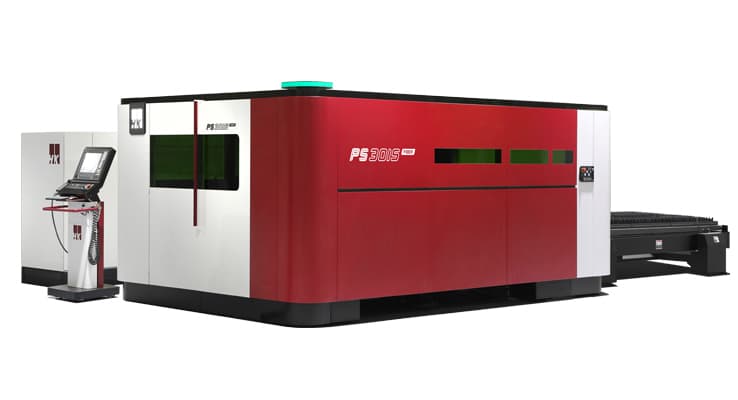

We offer a wide range of output powers for the lasers we sell. These fiber laser machines can perform work quickly and accurately at cutting speeds up to 35 m/s. m.

GSS Machinery boasts large manufacturing facilities and industry-leading equipment that make it an ideal partner for precision fabrication on large scale.

We can custom-make sub-systems and high level assemblies for cGMP compliance healthcare equipment.

International Technologies, Inc., is a customer-driven distributor for technologically advanced metal fabricating machines. We will work closely with you to offer the highest quality metal fabrication equipment and support your purchase throughout the product's life.

Laser Cutting Process Drawbacks

When compared to other techniques, laser cutting requires a high power consumption.

The laser beam is extremely delicate to handle.

If the laser beam comes into contact with human workers, it is hazardous.

Laser cutting is still unable to cut thick metals.

Thickness: A 40W to 45W CO2 laser, such as the Muse Core or 3D autofocus, can generally cut up to 14" thick wood, whereas a 90W tube laser, such as the P-Series PS24 or Muse Titan, can cut up to 12" thick wood.

The laser beam is the most important component of the laser cutter; it determines wavelength and power, and thus the material that it can cut or engrave. Solid-state lasers, fiber lasers, and CO2 lasers are the three main types of lasers used in laser cutting.