Precision Industries

For applications that require strict regulatory compliance and other challenges, such as critical environments, explore advanced manufacturing solutions.

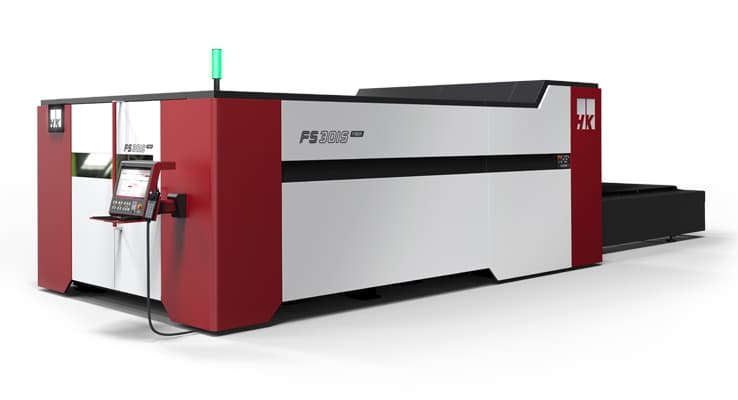

Gulf States Saw & Machine Co. sells a variety of marking devices in a range of power classes, with all the most common wavelengths (infrared and green), as well as a wide selection of lasers. These lasers are great for marking processes including engraving, annealing and discoloration. Gulf States Saw & Machine Co. has marking lasers that can process metals. They also have marking lasers that can process plastics and glass as well silicon, ceramics, organic substances, and other materials. Marking lasers can all be integrated into your existing system because they have the same modular design. The standard Gulf States Saw & Machine Co. delivery includes up to five different focusing opticals for each marking type, so you can get the best possible processing result regardless of what application.