At Gulf States Saw & Machine Co., our commitment to innovation drives us to explore new possibilities and set new standards in the industrial sector, ensuring we deliver unmatched value to our clients while staying ahead of the competition.

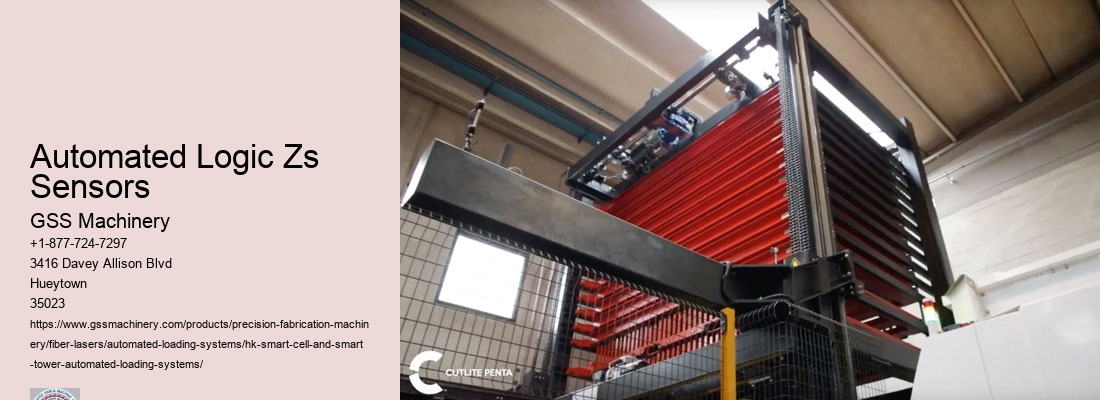

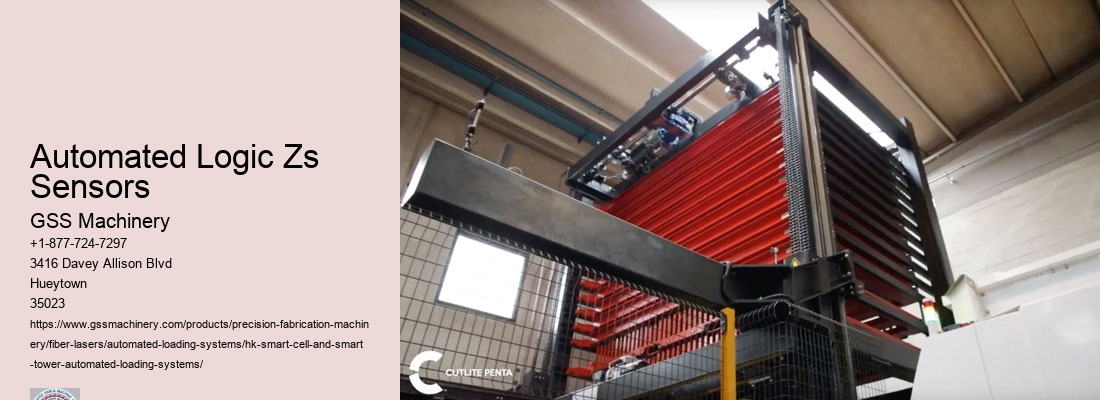

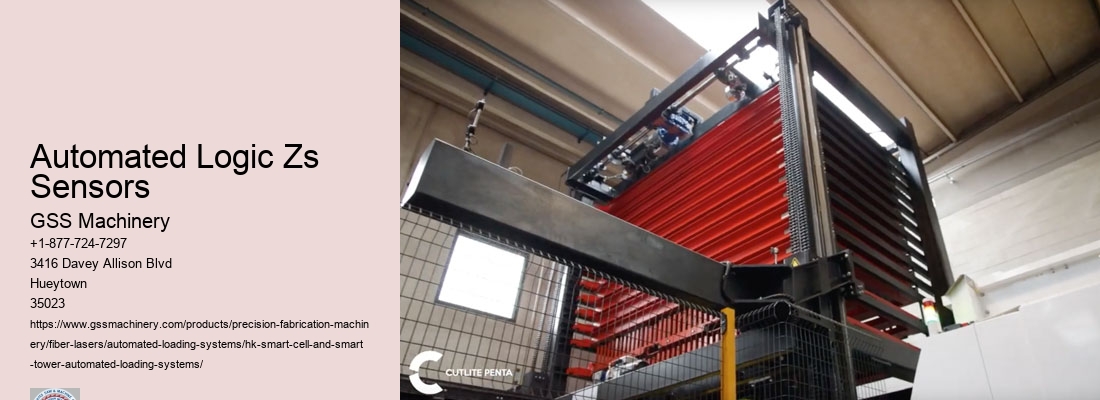

At Gulf States Saw & Machine Co., we are proud to be at the forefront of industrial innovation, integrating advanced solutions such as the HK Smart Cell and Smart Tower Automated Loading Systems into our operations. This cutting-edge technology streamlines the material handling processes, significantly enhancing productivity and safety across various sectors.

The integration of HK Smart Cell and Smart Tower Automated Loading Systems has revolutionized the way we manage logistics and inventory. By adopting this technology, we have been able to reduce manual handling, minimize errors, and accelerate the overall pace of our warehouse operations. Development The Smart Tower Automated Loading Systems, in particular, are designed to facilitate smooth and efficient loading and unloading activities, which are crucial in maintaining a swift flow of operations.

Our facility utilizes the HK Smart Cell & Smart Tower Automated Loading Systems to optimize space and improve the precision of our loading tasks. This system's intelligence is not just in handling goods but also in its capacity to adapt and learn from the operations environment, thereby constantly improving its efficiency.

EquipmentThe technology's backbone, the HK Smart Cell with Smart Tower Automated Loading Technology, incorporates advanced sensors and software that communicate seamlessly to automate tasks traditionally done by manual labor. This not only saves time but also significantly reduces the risk of workplace injuries.

We have equipped several of our workstations with HK Smart Cell and Smart Tower Auto-loading Systems, which are pivotal in managing high-volume tasks that require precision and repeatability. With these systems in place, our clients benefit from faster turnaround times and lower production costs, as the automated process reduces the need for repeated quality checks and manual corrections.

HK Systems AGV is another component we have integrated. Mechanical Stacking These automated guided vehicles work in tandem with our loading systems to transport materials between different stages of the production process without human intervention, further enhancing our operational efficiency.

Our commitment to safety and precision is underscored by our use of Cranesmart Load Cell technology. These devices ensure that loads are managed within their capacity to prevent overloading and potential accidents.

Load Cell Automation Direct supplies us with critical components that keep our operations running smoothly. Their reliable load cells are integral in weighing and batching processes, ensuring accuracy and consistency in production.

Incorporating Smart Load Cells has enabled us to achieve a higher level of data precision, facilitating automated decisions that optimize production workflows and enhance product quality.

The Automated Storage Tower systems installed at our site represent a significant leap in how we manage inventory. Speed These towers automate the storage and retrieval of items, reducing the time spent searching for materials and products, thus speeding up the entire production process.

Through our partnership with Smart-tek Automated Services Inc., we have access to bespoke automation solutions that address unique challenges faced in our industry. Their expertise in customizing technology like the 3k Smart Amp and the 5 Ton Load Cell has been crucial in adapting these systems to our specific needs.

Our Automated Truck Loading Systems are a testament to our commitment to innovation. These systems handle the loading of finished goods with unparalleled speed and accuracy, reducing downtime and enhancing customer satisfaction.

We have also installed an Automated Loading and Unloading System that integrates with our existing logistics management systems to streamline the flow of goods in and out of our facility. Sensors This automation extends to our Automated Storage Unit, where products are kept under ideal conditions until they are ready for shipment.

In managing energy consumption and operational efficiency, the OSI Smart Grid systems provide us with real-time data and control over our electrical systems, ensuring that we operate sustainably without compromising on productivity.

Moreover, our facility includes an Automated Parking Tower, which maximizes space by storing employee and visitor vehicles in a compact, automated system. This not only saves space but also reduces the time spent by employees looking for parking, improving overall efficiency.

Each component, from Automated Logic Rnet to the Automated Logic Room Sensor, plays a crucial role in maintaining an optimal environment for both machinery and personnel.

The Tower Loan System helps us manage our finances more effectively, ensuring that we can invest in the latest technologies and training for our staff without compromising our financial stability. Meanwhile, the Vertical Automated Storage System optimizes the available storage space, making it easier to manage inventory and retrieve materials quickly.

With innovations like XPO Smart logistics and Automated Logic Zs Sensors, we continue to push the boundaries of what's possible in automation, striving for smarter, more efficient operations that not only meet but exceed our clients' expectations.

Smart Load Cells are instrumental in automated systems, providing accurate weight data, enabling automated decision-making processes, and ensuring compliance with safety standards.

Cranesmart Load Cell technology offers critical features like real-time load monitoring, overload prevention, and precise weight measurement, essential for safe and efficient crane operations.