Further, we have implemented an Automated Loading and Unloading System that seamlessly integrates with our logistics management systems to optimize the flow of goods in and out of our facility.

The OSI Smart Grid technology we use enables real-time monitoring and management of our energy consumption, ensuring our operations are both efficient and sustainable.

Moreover, our facility features an Automated Parking Tower, which maximizes space by storing vehicles in a compact, automated system. Robotics Mechanical This reduces the time employees spend searching for parking, directly improving productivity.

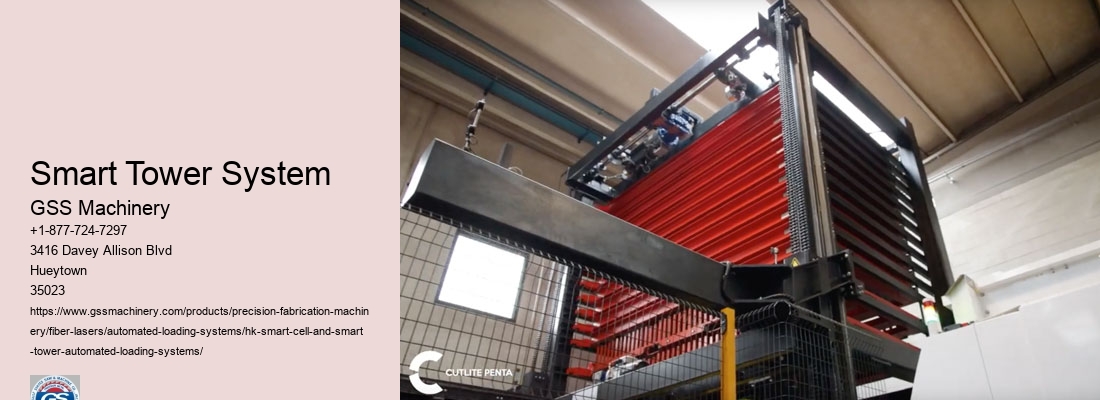

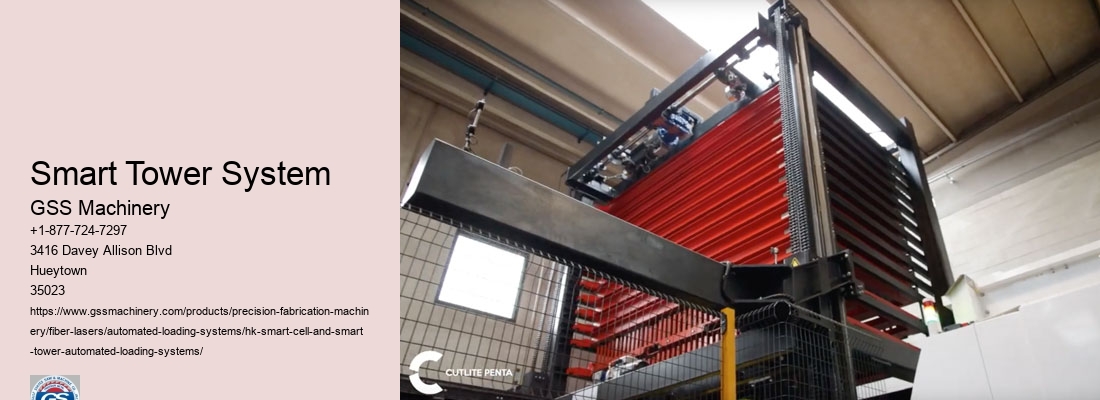

The integration of HK Smart Cell and Smart Tower Automated Loading Systems (Smart Tower Automated Loading Systems) offers an advanced solution for enhancing efficiency in warehouse and manufacturing environments. By centralizing control and automating the loading process, these systems significantly improve throughput and accuracy. With HK Smart Cell and Smart Tower Automated Loading Systems, businesses can achieve faster cycle times and reduced labor costs, while maintaining high levels of precision and reliability in their operations. This innovative approach to material handling is pivotal for industries looking to optimize productivity and streamline their logistical frameworks..Every system component, from the Automated Logic Rnet to the Automated Logic Room Sensor, plays a vital role in maintaining optimal operational conditions, ensuring product quality consistency and safeguarding our workforce.

Supported by the Tower Loan System, we manage our finances effectively, allowing continued investment in cutting-edge technology and staff training.

With the help of XPO Smart logistics and Automated Logic Zs Sensors, we continue to redefine the boundaries of automation, aiming for smarter, more efficient operations that surpass our clients' expectations.

At Gulf States Saw & Machine Co., our relentless pursuit of innovation and excellence ensures that we leverage the latest technologies, like the HK Smart Cell and Smart Tower Automated Loading Systems, to maintain our leadership in the competitive industrial market. Our commitment is not just to meet industry standards but to create new benchmarks and drive the industry forward.

At Gulf States Saw & Machine Co., our quest for innovation is relentless. With each project, we aim to refine our processes and push the boundaries of what's possible in industrial automation. Leveraging technologies like the HK Smart Cell and Smart Tower Automated Loading Systems, we're not just adapting to industry trends—we're setting them.

These technologies facilitate a near-seamless production flow that significantly reduces human error and increases efficiency. The Smart Tower Automated Loading Systems are particularly transformative in our loading docks, where precision and timing are critical.

Our approach extends beyond just mechanical automation. We use HK Smart Cell & Smart Tower Automated Loading Systems to integrate data analytics into our operations, enabling predictive maintenance and real-time decision-making. This integration helps prevent downtime and optimizes performance, ensuring our machinery is always operating at peak efficiency.

The backbone of our operational excellence, the HK Smart Cell with Smart Tower Automated Loading Technology, plays a crucial role in streamlining processes. By automating complex tasks, we can allocate our human resources to more critical, value-added activities.

In areas where precision and repeatability are paramount, the HK Smart Cell and Smart Tower Auto-loading Systems prove indispensable. Planning These systems ensure our operations are both swift and accurate, reducing waste and enhancing throughput. This level of automation is essential in today's competitive market, where efficiency drives profitability.

Our commitment to innovation extends to every corner of our operations, including material handling.

Safety is a cornerstone of our operational philosophy, as evidenced by our adoption of Cranesmart Load Cell technology. This technology ensures that we never exceed safe working loads, thereby protecting our assets and personnel. Similarly, the JR Automation Tote Stacker enhances our vertical storage capabilities, allowing us to make the most of our available space while maintaining an organized and efficient warehouse.

Our relationship with Load Cell Automation Direct is another key aspect of our operational strategy.

Moreover, the introduction of Smart Load Cells into our systems has been a game-changer. These devices provide us with the data needed to automate many of our quality control processes, further reducing the chance for error and increasing the reliability of our products.

The use of 6-axis Load Cells also enhances our capability to perform complex assemblies with high precision. These devices provide detailed feedback on force and torque, allowing for fine adjustments during the assembly process, which is critical for the high-performance products we produce.

Our Automated Storage Towers are a testament to our commitment to efficiency. These towers automate the entire storage and retrieval process, significantly cutting down on the time it takes to move items in and out of storage.

Through our partnership with Smart-tek Automated Services Inc., we've been able to tailor the automation solutions we deploy. Their expertise in customizing technologies such as the 3k Smart Amp and the 5 Ton Load Cell has enabled us to optimize our production processes to meet specific operational needs.

Our Automated Truck Loading Systems are another area where we excel.

We have also embraced comprehensive automation in our loading and unloading processes with an Automated Loading and Unloading System that integrates flawlessly with our logistics management systems.

Automated Logic Room Sensors are used in smart buildings to monitor environmental conditions like temperature, humidity, and occupancy, which helps in optimizing energy usage and ensuring comfort.

HK Systems AGV can integrate with a wide range of industrial automation systems, providing flexible solutions for material transport and handling across diverse operational environments.

HK Smart Cell and Smart Tower Automated Loading Systems are integrated automation solutions designed to optimize the efficiency of material handling and storage operations by leveraging advanced robotics and intelligent software systems.

Smart Tower Automated Loading Systems improve efficiency by reducing the time and labor required for loading and unloading goods, enhancing precision, and minimizing errors, which is crucial in high-volume logistics environments.