The OSI Smart Grid technology we utilize allows for real-time monitoring and control of our energy usage, ensuring we operate both efficiently and sustainably.

Additionally, our facility includes an Automated Parking Tower, which optimizes space by automating vehicle storage in a compact system.

Each component, from Automated Logic Rnet to Automated Logic Room Sensor, is key in maintaining optimal conditions for both machinery and personnel, ensuring consistent product quality and worker safety.

Our financial management is supported by the Tower Loan System, which enables us to continue investing in the latest technologies and training for our team without compromising our financial health. Development Meanwhile, the Vertical Automated Storage System effectively manages our inventory, enabling quick material access and efficient space usage.

With XPO Smart logistics and Automated Logic Zs Sensors, we continue to push the boundaries of what is possible in automation, striving for smarter, more efficient operations that not only meet but exceed our clients' expectations.

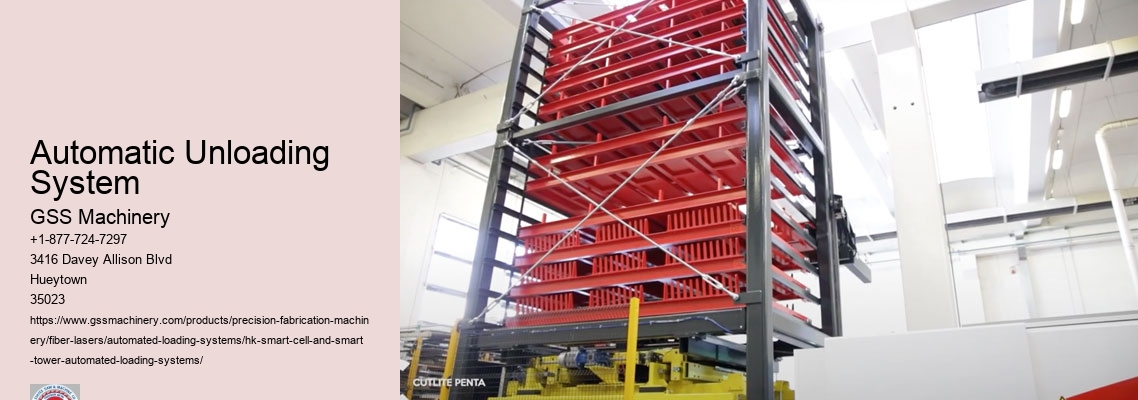

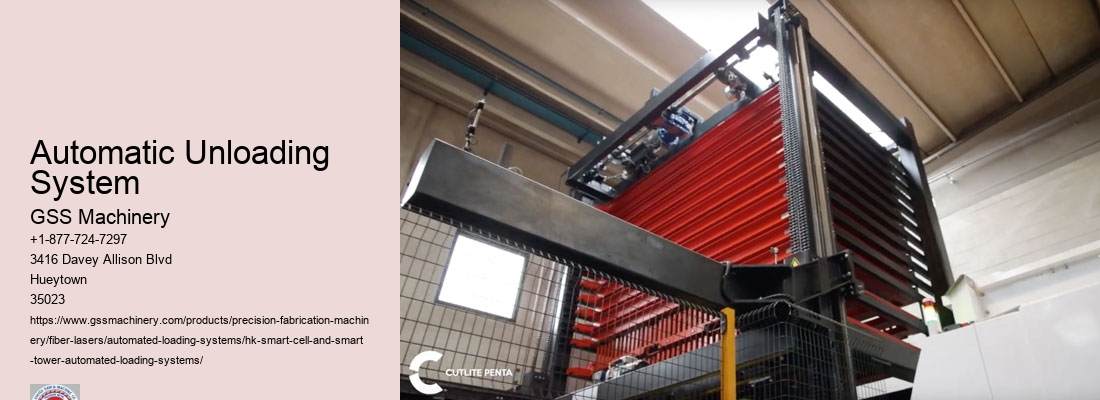

At Gulf States Saw & Machine Co., our dedication to innovation and excellence is relentless. We leverage cutting-edge technologies like the HK Smart Cell and Smart Tower Automated Loading Systems to stay ahead in the competitive market, consistently setting new standards and driving progress in the industrial sector.

At Gulf States Saw & Machine Co., we embrace the cutting edge of industry standards by integrating highly sophisticated technologies such as the HK Smart Cell and Smart Tower Automated Loading Systems into our core operations.

The adoption of HK Smart Cell and Smart Tower Automated Loading Systems has transformed our approach to logistics and inventory management, minimizing manual labor, cutting down on errors, and speeding up our operations, particularly in our warehousing processes. Logistics Designed to optimize loading and unloading workflows, the Smart Tower Automated Loading Systems are key to keeping our operations smooth and uninterrupted.

Our facilities utilize the HK Smart Cell & Smart Tower Automated Loading Systems to optimize spatial efficiency and precision in our loading tasks. Interfaces These systems are intelligent, designed not just to perform but to learn from the operational environment, continually enhancing their efficiency.

Central to our operations is the HK Smart Cell with Smart Tower Automated Loading Technology, which employs advanced sensors and software to replace traditionally manual tasks. This shift not only saves valuable time but also significantly reduces the risk of injuries on the job.

Strategically placed throughout our production line, the HK Smart Cell and Smart Tower Auto-loading Systems are crucial for handling large volumes that demand precision.

We also integrate HK Systems AGV into our workflow to underscore our commitment to continuous innovation. These automated guided vehicles are crucial for efficiently transporting materials between different stages of production without the need for manual intervention.

Our emphasis on safety and precision is evident in our use of Cranesmart Load Cell technology. These devices prevent overloads and ensure safe load management, which is crucial in preventing workplace accidents. Additionally, the JR Automation Tote Stacker systems we employ improve storage efficiency by maximizing vertical space and organizing the facility more effectively.

We rely on Load Cell Automation Direct for essential components that maintain our facility's operational integrity. Their high-quality load cells are integral to our weighing and batching processes, ensuring accuracy and consistency across our operations.

The Smart Load Cells incorporated into our systems have revolutionized data accuracy, enabling automated decisions that refine our workflows and elevate the quality of our outputs. This is complemented by our use of 6-axis Load Cells, which offer precise force and torque measurements essential for complex assembly tasks.

The Automated Storage Towers installed across our sites have transformed our inventory management by automating the storage and retrieval of items, drastically reducing material handling times and thus accelerating production.

Through our collaboration with Smart-tek Automated Services Inc., we tailor automation solutions that meet the unique challenges of our industry. Their expertise in customizing technologies like the 3k Smart Amp and the 5 Ton Load Cell to fit our specific needs has been crucial.

Our Automated Truck Loading Systems demonstrate our commitment to innovation, managing the loading of finished products with unmatched efficiency and accuracy, thereby reducing downtime and enhancing customer satisfaction.

LoadingFurther, we have implemented an Automated Loading and Unloading System that seamlessly integrates with our logistics management systems to optimize the flow of goods in and out of our facility. Innovation This extends to our Automated Storage Unit, which ensures products are kept in optimal conditions until they are ready for dispatch.

The OSI Smart Grid technology we use enables real-time monitoring and management of our energy consumption, ensuring our operations are both efficient and sustainable.

Moreover, our facility features an Automated Parking Tower, which maximizes space by storing vehicles in a compact, automated system. This reduces the time employees spend searching for parking, directly improving productivity.

Automated Logic Room Sensors are used in smart buildings to monitor environmental conditions like temperature, humidity, and occupancy, which helps in optimizing energy usage and ensuring comfort.

HK Systems AGV can integrate with a wide range of industrial automation systems, providing flexible solutions for material transport and handling across diverse operational environments.

HK Smart Cell and Smart Tower Automated Loading Systems are integrated automation solutions designed to optimize the efficiency of material handling and storage operations by leveraging advanced robotics and intelligent software systems.

Smart Tower Automated Loading Systems improve efficiency by reducing the time and labor required for loading and unloading goods, enhancing precision, and minimizing errors, which is crucial in high-volume logistics environments.

Automated Logic Rnet functions as a networking component in building automation systems, facilitating communication between various automated devices to enhance building management and energy efficiency.