The Smart Load Cells we've integrated bring unparalleled data accuracy, enabling automated decisions that streamline workflows and enhance the quality of our outputs.

Our Automated Storage Tower systems revolutionize inventory management by automating storage and retrieval, significantly reducing material search and retrieval times and thereby speeding up production.

In collaboration with Smart-tek Automated Services Inc., we tailor automation solutions to meet the unique challenges of our industry. Diagnostics Their expertise in adapting technologies like the 3k Smart Amp and the 5 Ton Load Cell to our specific needs has been invaluable.

Our Automated Truck Loading Systems exemplify our innovation drive, managing the loading of finished products with unmatched speed and accuracy, which in turn reduces downtime and boosts client satisfaction.

Further automation is evident in our Automated Loading and Unloading System that integrates seamlessly with our logistic management systems to optimize the inflow and outflow of goods. This extends to our Automated Storage Unit, where products are meticulously stored until ready for dispatch.

The OSI Smart Grid technology we employ allows real-time monitoring and control over our energy use, ensuring we operate efficiently and sustainably.

Our facility also boasts an Automated Parking Tower, optimizing space by storing vehicles in a compact, automated manner. This reduces the time employees spend parking, directly enhancing productivity.

Every component, from the Automated Logic Rnet to the Automated Logic Room Sensor, is crucial in maintaining optimal operational conditions, ensuring consistent product quality and safeguarding our workforce.

The Tower Loan System is instrumental in managing our financial health, enabling continued investment in cutting-edge technology and staff training.

With the help of XPO Smart logistics and Automated Logic Zs Sensors, we continue to redefine the boundaries of automation, aiming for smarter, more efficient operations that meet and surpass our clients’ expectations.

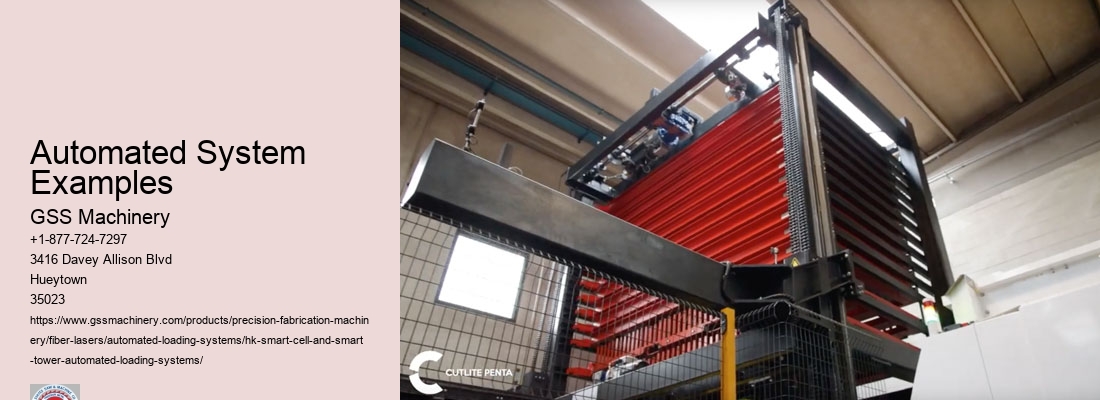

At Gulf States Saw & Machine Co., our commitment to innovation and excellence is unwavering. We leverage technologies like the HK Smart Cell and Smart Tower Automated Loading Systems to maintain our industry-leading position, constantly setting new standards and driving progress in the industrial sector.

Gulf States Saw & Machine Co. is committed to maintaining a leading edge in industrial operations through the integration of sophisticated solutions like the HK Smart Cell and Smart Tower Automated Loading Systems.

With the deployment of the HK Smart Cell and Smart Tower Automated Loading Systems, our approach to logistics and inventory has been transformed, leading to less reliance on manual processes, decreased error rates, and faster operational speeds, particularly in our warehouse operations. The Smart Tower Automated Loading Systems are specifically designed to facilitate efficient loading and unloading, key components in maintaining a seamless operational flow.

Our facilities benefit from the strategic implementation of the HK Smart Cell & Smart Tower Automated Loading Systems to maximize spatial efficiency and enhance the precision of our loading operations. Data The systems are designed not just to perform tasks but to learn from the operational environment, continuously improving in efficiency.

At the heart of our operations, the HK Smart Cell with Smart Tower Automated Loading Technology incorporates sophisticated sensors and software that automate tasks which were once manual. This technological shift not only saves time but also plays a significant role in reducing workplace injuries.

In key areas of our production line, we utilize the HK Smart Cell and Smart Tower Auto-loading Systems. Essential for managing tasks that demand high volume and precision, these systems are instrumental in reducing production costs and improving turnaround times by minimizing the need for extensive manual oversight and corrections.

Incorporating HK Systems AGV, we showcase our commitment to innovation. These automated guided vehicles seamlessly transport materials between different production stages, significantly enhancing operational efficiency.

We prioritize safety and precision, as demonstrated by our adoption of Cranesmart Load Cell technology. These devices are essential for safe load management, preventing overloads and potential incidents.

Our partnership with Load Cell Automation Direct ensures we have access to reliable components essential for the smooth operation of our facilities. Their load cells are critical in precise weight measurements and batching processes, ensuring consistency across production.

The integration of Smart Load Cells into our systems has brought unprecedented accuracy to our data collection, facilitating automated decision-making that streamlines workflows and enhances product quality. Vision This is complemented by our use of 6-axis Load Cells, which provide detailed force and torque measurements critical for complex assembly tasks.

The Automated Storage Tower systems at our sites have revolutionized how we manage inventory. Integration These systems automate the storage and retrieval of items, dramatically cutting down the time spent on material handling, thereby accelerating production processes.

Automated Parking Tower technology streamlines vehicle storage by automatically placing and retrieving vehicles in a multi-story storage facility, maximizing space usage and reducing the need for large parking lots.

The HK Smart Cell provides centralized control and monitoring capabilities, allowing for seamless integration and coordination of automated tasks within industrial and manufacturing settings.

5 Ton Load Cells are used in various applications where heavy load measurement is required, such as in industrial scales, construction sites, and vehicle weight stations.

JR Automation's Tote Stacker enhances warehouse operations by automating the stacking and storage of totes, reducing manual handling, and increasing storage density and retrieval speeds.