What is the function of a coping in building construction

Voortman Clipper CNC Angle Line and Voortman CNC Drill Line introduced affordable automation to beams and angles for small-to-medium fabricators. Voortman Liberator is similar in that it allows automated beam coping into shops that might not otherwise have considered it.

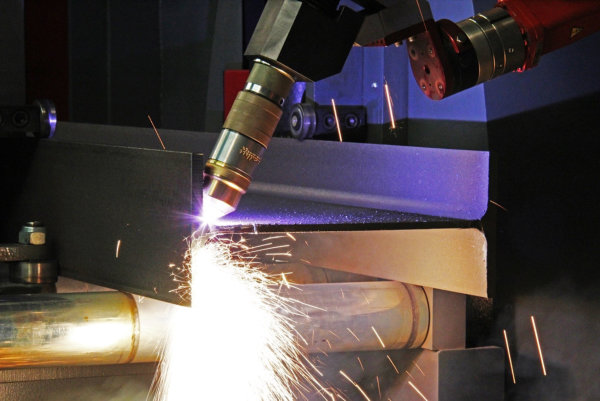

FANUC's robotic arm can be angled 360 degrees. This allows it to quickly and easily cut any shape or profile required for coping beams. This versatility is coupled with the superior power and flexibility of Hypertherm-X-Definition Plasma.