Hgg Rpc 1200

The factory trained service tech will spend about 5 days at your site installing the machine, calibrating it, and re-training operators. This will give you more than enough hands-on experience, and also help with troubleshooting, maintenance, and diagnostic training.

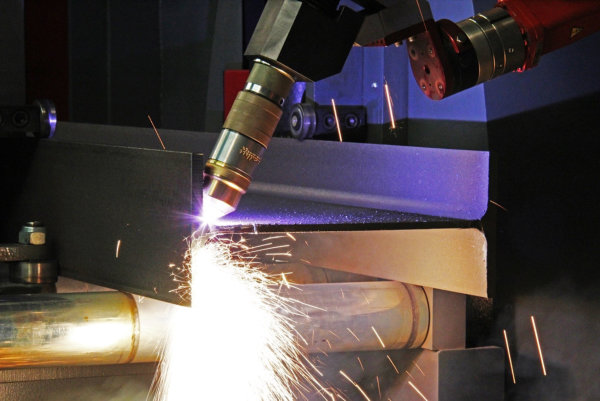

This CNC beam coper with single torch eliminates the need for manual laying of your copes. Instead, it makes sure that your CNC detail drawings are accurate and precise and your copes are completed neatly.