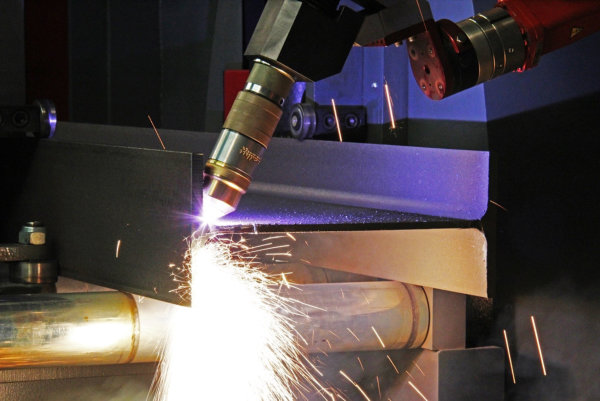

Robot

The single torch CNC beam coper eliminates the need to manually lay out your copes. It does this by transferring your CNC detail drawings directly from the CNC.

A CNC beam coping machine is safer than a handheld torch. Remote operation of the machine allows the operator to control it remotely, which moves him further away from the cutting flame.