Your detailer then will provide you with a DWG / LTP / PDF file that can be used to print or plot your drawings. He will also provide the NC1 and NC2 files that you can directly import into your machine. Voortman comes standard with the DSTV - Import function.

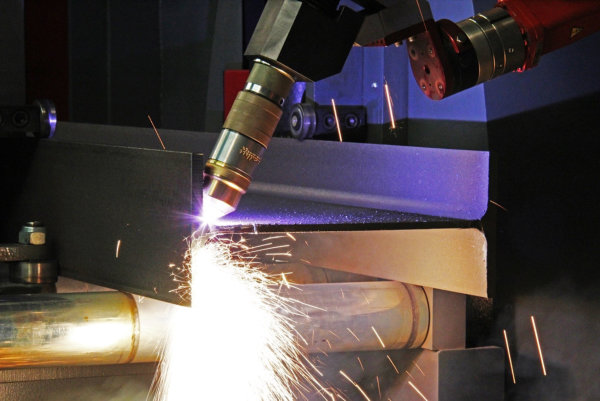

The basic unit consists of a semi-automatic, oxygen-fuel coping device. Operator positions the workpiece, adjusts the torch height, and fine tunes it. There is also an automated option that allows the laser to probe the area and set its torch height automatically. The basic unit is equipped with powered conveyors. This allows the operator to measure and mark the feedstock's X length before it can be cut. An optional automated measuring system can be added via Laser measurement of the feed stock. The operator can input the type of material to be cut using the interface. The computer touch screen displays a list of choices that the operator can scroll through. The computer has all dimensions for the AISC structural metal. It is possible to program the computer with a fully dimensioned handle drawing. This simplifies the process and reduces errors. The operator can customize and override any input and save it as a new programme, if necessary. The machine can be programmed remotely using DSTV exported drawing. Operators can control the equipment using a wireless remote. This allows the operator to view from any angle necessary to inspect operations and keep accuracy. The operator places his mark on the material, moves it into place, clamps hydraulically the material to be cut, and then checks for accuracy. The laser is aligned by the operator, and the cycle starts. The torch lights, preheating the material. The operator initiates the cutting process by hand and completes the job as long as the torch height remains constant.