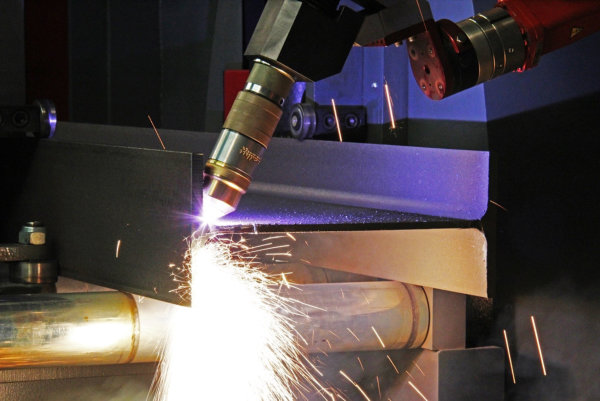

Beam Coping Machine Attachment

Voortman will help you cut production time by 80%. This is an excellent return on investment. This beam coping machine is the industry leader and comes with free, unlimited support. Turnkey installation and training are available anywhere in the U.S.

Our office hours open from 8am until 5pm Eastern Time. We are well-versed in all aspects and will gladly assist you with technical issues during business hours.