Carbide

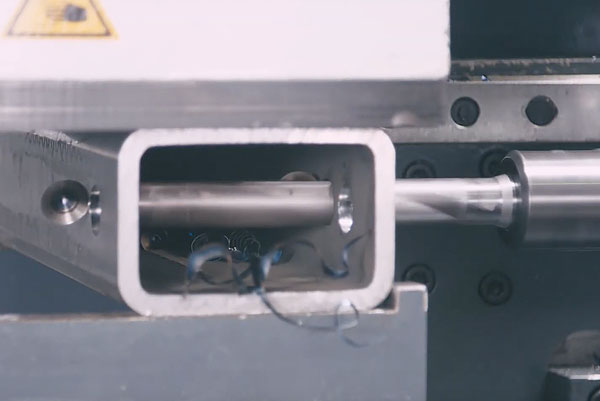

Let�s compare Twist Drill Bits and Insert Drill bits in the real life fabrication situation. We will just look at one example � 13/16? (22mm), which is typically the most commonly drilled hole diameter.

".. This machine is designed for Structural fabricators. But I knew it would work well for drilling trucks frames. The assembly was flawless due to the machine's repeatability and accuracy. Avenger drills one channel for a truck in just two hours. We would have taken 16 hours if it was done manually. The machine has increased our productivity AND profitability !.."