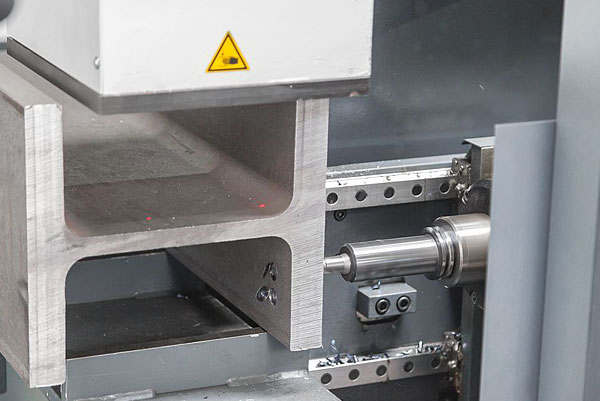

Cnc Beam Drill Line Boring Machine

To service our global clientele, Voortman proudly provides our partners with 24 hour technical support. Voortman� inside service staff have years of experience in the field, assembly, or factory checkout which provides them with hands-on experience with most machines. At Voortman their service staff is not only available when you need them, but they maintain superior knowledge to solve questions as they arise.

It is obviously preferable to import files directly from your steel detailing software because it eliminates an unnecessary step and also eliminates possible incorrect data capture. There are two separate and distinct camps in this respect: